Reducing Cost by Lowering Embankment Height: Developing a “Composite Box Culvert” that does not Require Earth Covering

Many arterial high-standard highways (expressways) in flat regions are built in a form requiring earth covering, and thus minimizing the height of embankments leads to lower construction costs.

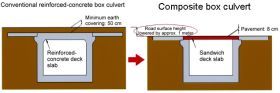

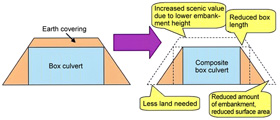

Given that embankment height is determined by the reinforced-concrete box culverts (box-like structures) that are built at intersections of high-standard highways and existing roads, the Structures Research Team embarked on R&D toward developing a new type of box culvert. For this new box culvert, a “sandwich” structure made up of concrete that is inserted into a steel plate is employed in the roof section (deck slab). This structure is also being used in bridge floor plates. It is lightweight and has superior rigidity and durability, and can reduce thickness by half compared to conventional reinforced-concrete deck slab. Moreover, although conventional box culverts required an embankment of at least 50 centimeters above the deck slab, pavement can be placed directly on top of the new type. Consequently, vehicles can pass directly over the box culvert without the need for the embankment that is conventionally required. This makes it possible to lower the height of the embankment by roughly one meter compared to when a conventional box culvert is used, thus reducing the amount of embankment used for the entire high-standard highway and lowering cost. This method employing a sandwich-type deck slab in the roof is called a “composite box culvert.” Its use reduces cost because it lowers the amount of embankment used as well as the area of land needed. It is also expected to increase the scenic value of highways by lowering embankment height.

As part of our development of the sandwich deck slab, we are conducting a variety of static loading tests as well as loading tests using a wheel running machine to confirm resistance to fatigue damage caused by the passing of large vehicles. Also, using a newly constructed composite box culvert, we are measuring deflection by driving trucks loaded with gravel across the deck slab to verify the validity of the design method.

The composite box culvert can be expected to significantly lower cost in the construction of embankment-type high-standard highways, and particularly those built in flat areas. It is our hope that it will prove useful as a construction method in cost-reduction measures.

(Contact: Structures Research Team, CERI)