Research on the Recycling of Aged Asphalt Pavement

Figure 1. Recycle process of aged and waste asphalt pavement materials |

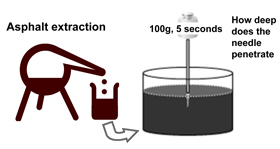

Figure 2. Asphalt Solvent Extraction and Quality Testing |

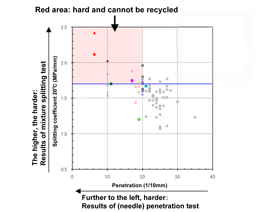

New method of evaluation testing |

Recycling of asphalt pavement material

Road pavement in Japan, which was constructed rapidly during high speed

economic growth after the Second World War, includes a vast quantity of

asphalt pavement. Although pavement surfaces material used to be dumped

at final disposal sites after servicing, beginning in the early 1970s,

recycling technologies (Fig. 1) were developed. Standards were provided

in the late 1980s, and asphalt pavement recycling became widely used procedures

all over the country. As a result, the recycling rate of materials from

asphalt pavement reached the extremely high level of 98% in 2000, and this

recycling rate has been maintained in subsequent years. Asphalt pavement

is now repeatedly reused, earning it the title, the "honor student"

of recycling promotion.

Changing quality of asphalt material caused by deterioration

But because recycling pavement has widely penetrated to become common practice, the quantity of asphalt pavement materials reused several times is increasing, and it is assumed that the quantity of asphalt which has deteriorated over time is increasing. Thus, recycling quality standards which can be maintained even through repeated use are now necessary. And recently, because of multiple functions requirement, and polymer modified asphalts such as porous pavement which prevents water from accumulating on road surfaces, is coming into wide use. There is an issue of concern that progressing material deterioration and the mixing in of polymer modified materials may lead to an increase in pavement materials failing to conform with present standards. Polymer modified asphalt faces problems: in some cases it resists dissolution by organic solvents, or existing quality assessment methods (Fig. 2) cannot be applied to it. So it is necessary to establish advanced recycling technologies which account for changes of quality of pavement materials.

Method of evaluation testing for recycled asphalt pavement materials

In order to appropriately recycle pavement materials of various qualities, it is necessary to accurately evaluate the quality of pavement materials and design mixtures necessary for their reuse. This research is studying on new evaluation and testing methods which test how easily estimate aging and/or modification, and the qualities of additive (rejuvenator) used for recycling, intending to clarify long-term durability.

Based on past achievements, this research has obtained a testing method which can be used to evaluate aged asphalt and modified asphalt based on identical standards, and which does not use organic solvents. Furthermore, through a variety of material tests and use of trial paving on actual roads, we have investigated criteria for material mixing rates sustainable through repeated recycling, the quality of recycling additives, and so on.

(Contact: Advanced Materials Research Team, Pavement Research Team)