Hydraulics and Sediment Transport Engineering Team

DAM HYDRAULIC LABORATORY AND ANNEX

Japan has a long history of dam construction, maintenance and improvement. And has approximately 2,600 dams (higher than 15m) till now. More than 90% of the total capacity in Japan, however, has been created since 1950. High and large capacity dams have been constructed in this duration supported by economical and technological development. There are some kinds of dam projects in Japan. Electric companies construct dams for power generation, Ministry of Agriculture, Forestry and Fisheries, construct for irrigation. Ministry of Land, Infrastructure, Transport and Tourism

(MLIT) and prefecture governments also construct dams for multi purposes, which include flood control because these governments are responsible for river management.Dam Hydraulic Laboratory (L102m×B44m) and its Annex (L70m×B29m) are used for investigation of the hydraulic phenomena concerning dams’ reservoirs and hydraulic facilities such as spillways, outlet works and intake systems. Also, laboratories are used for hydraulic design of facilities of governments’ dams especially of MLIT dams. Hydraulic design of almost all spillways and outlet works of MLIT dams are executed through model tests in these laboratories.

Water release facilities (spillways, flood control facilities and so on) are hydraulically designed using three dimensional model tests with some scales. Flow conditions, hydraulic characteristics such as pressure acting on structure walls, water level in waterways, discharge rate of gates etc. are checked and improved.

New type gate (Tension radial gate) was developed through the experimental comparison of several type models. (scale 1/13)

Stepped chute of rock-fill dams’ spillway reflecting site topography is examined for effective energy dissipation and excavation reduction. (scale 1/62.5)

Labyrinth type wires on the CSG (concrete sand and gravel) dam was tested for shortening spillway length to reduce the training wall length . (scale 1/20)

The capacity for 100 years of sediment deposition is usually set bellow the effective capacity of a dam reservoir in Japan. However, the increase of operation experiences or the larger deposition volume than the estimation requires sediment countermeasures for some sever condition dams. Recently sediment release methods to the downstream areas are also required for river restoration. Development of structural design methods concerning the reservoir sedimentation is one of the main item of the laboratory.

Sediment bypass facility, which bypasses sediment inflow from the upstream end of the reservoir to the area of dam downstream is examined. The facility is operated during flood and bypass a part of flood inflow discharge include sediment. (scale 1/50)

Facilities for the only flood control dam is examined with the sediment performance in the reservoir. Recently, flood control facilities of only flood control dam are located near the river bed elevation to release sediments to the area downstream. (scale 1/62.5)

Countermeasures against debris inflow are also examined for the facilities of only flood control dam.

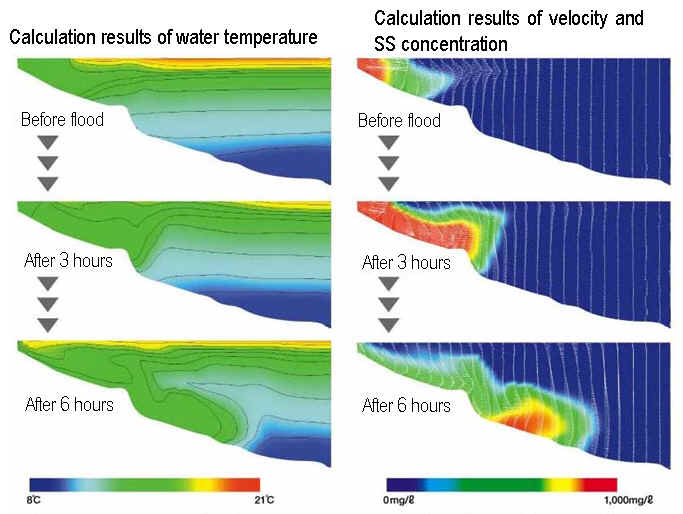

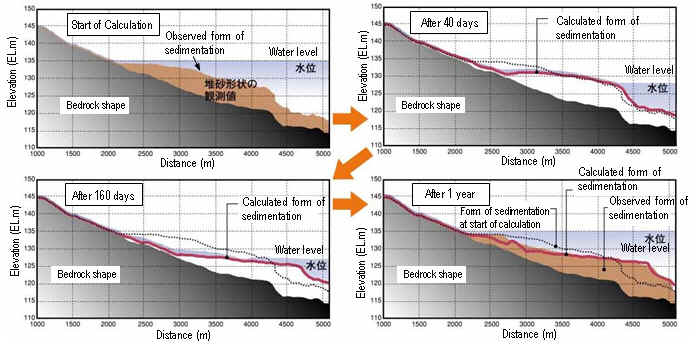

Phenomena in a whole size of a reservoir concerning water quality, water temperature and sedimentation cannot be realized by a model. The application of model examination is limited. Numerical simulation model is also developed to examine intake facilities, water quality conservation systems, sedimentation countermeasures and so on.

Numerical simulation using turbulent model is examined for estimating turbid water performance during flood.

Riverbed evolution calculation model for various sediment size is under developing to forecast and ensure the efficiency of sedimentation countermeasures.

Copyright (C) 2016 Public Works Research Institute.