"Technical Standard for Road Tunnel (for Ventilation) and Practical Guide" Revised

In relatively long road tunnels with heavy traffic, ventilation facilities for ensuring a safe and comfortable environment in tunnels (Figure-1) are required. The design of road tunnel ventilation facilities is implemented based on standards called the Technical Standard for Road Tunnel. The practical design is made according to the guide for these standards entitled the Technical Standard for Road Tunnel (for Ventilation) and Practical Guide (Japan Road Association) so as to satisfy the specified criteria of the concentration of smoke and CO in tunnels based on emissions per small- and large-sized vehicle and on the conditions such as the traffic volume and tunnel length.

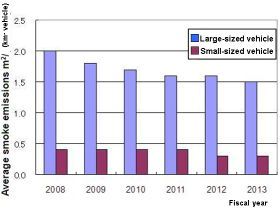

Up to this point, design has been based on the guide revised in 2002. However, situations related to road tunnel ventilation facilities have been changing, as with the reduction of emission gas concentration achieved by improved vehicle performance due to enforced automobile exhaust gas regulations, the increase in number of light vehicles owned nationwide, etc. Accordingly, the need has arisen to revise the values used in design to reflect changes in the situation in order to promote more rational ventilation design.

PWRI's Tunnel Research Team has been working on surveys and studies of

actual conditions regarding the following for the rational design of ventilation

facilities: Recently, the 2008 Revised Technical Standard for Road Tunnel

(for Ventilation) and Practical Guide were released in October 2008. It

incorporates achievements of PWRI's activities.

(1) Smoke emissions per vehicle

The conditions of actual in-service road tunnels were surveyed (Photo-2) in order to understand and predict smoke and CO emissions per vehicle. The smoke emissions per vehicle (Figure-1) to be used for the design of ventilation facilities have been proposed based on this survey.

(2) Velocity gradient correction coefficients for smoke emissions

Smoke emissions may vary depending on road longitudinal gradient, vehicle speed, etc. and velocity gradient correction coefficients have been proposed in light of the vehicle composition ratio.

(3) Equivalent resistance area of vehicles

Driving a vehicle in a tunnel causes air to move. The degree of air movement changes the smoke concentration in the tunnel. For this reason, an equivalent resistance area for finding the amount of air moved by a vehicle in a tunnel has been proposed in consideration of change of vehicle shape and vehicle model in recent years.

(Contact: Tunnel Research Team)

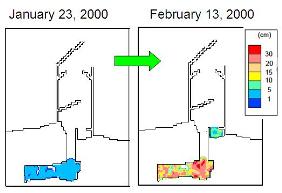

Development of Harbor Freezing Simulation

In harbors and fishing ports from the northern to eastern parts of Hokkaido, harbor freezing, in which water surface in harbors becomes frozen, occurs in winter. This causes damage such as hindrance of vessel operation, departure of fishing boats, and damage to ship hulls. There are various causes of harbor freezing in Hokkaido. In addition to the obvious severe cold environment of Hokkaido, several characteristics can be found by the region. In fishing ports and harbors facing the Okhotsk Sea, drift ice has a reasonable influence. Along the Sea of Japan, large amounts of snowfall reduce the salt content and temperature of seawater, and the fallen snow may turn into ice without melting first. On the Pacific side, freezing does not occur often but some harbors are quite prone to freezing due to harbor shape and structure. The artificially-excavated Otsu Port (Toyokoro Town in Hokkaido), for example, is an enclosed, artificially-excavated port that is very prone to freezing for reasons including: (1) the thermal capacity is small and the water temperature quickly falls to freezing, (2) not much heat exchange takes place with the open sea and (3) the frozen ice is not easily discharged/moved to the open sea. The principle is the same as that of enclosed and shallow pools prone to freezing. To reduce the hindrance to harbor use due to harbor freezing, several measures can be considered including supplying heat, employing new harbor shapes/construction of new anchorages, and eliminating formed ice/ice crystals out of the harbors. However, no methodology was available to quantitatively assess the effect of construction.

To identify the harbor freezing mechanism, we have developed a practical freezing simulation tool to assist in the study of the effects of the proposed construction countermeasures while conducting field observations on the mechanisms of ice crystal generation, heat balance, etc. This system considers the three layers of snow, ice, and water in view of the actual weather conditions and calculates the thickness of the snow and ice based on the surface heat balance or inter-layer interface. In addition, the system also takes into account the flow fields in and out of harbors and movement of ice floes due to wind and flow, and is also capable of reproducing planar freezing conditions. As a practical application, this simulation was used at Otsu Port, mentioned above, where countermeasures for freezing were eagerly desired. This led to a comparison of the effects of the different construction work countermeasures mentioned above. As a result, the construction of a new anchorage (securing mooring in a water area close to the outside of the port with heat exchange taking place frequently) was proposed as the most appropriate technique for the site; this proposal was made into a project. This simulation is also used for studying anti-freezing measures in fishing ports in eastern Hokkaido. The achievements of this research have been published in foreign journals and their benefits are publicized overseas as well.

(Contact: Port and Coast Research Team, CERI)