Development of a drainage pump installation support system

In recent years, rain has fallen even in winter in Hokkaido, melting accumulated snow and causing more severe flood damage than normally associated with such amounts of rainfall.

It is necessary to depend on pump trucks to drain water particularly in low-temperature and snow-covered conditions, since drainage pump stations may not be used due to freezing and other reasons. Furthermore, there are factors that cause delays in winter operation, such as the necessity for snow removal, and deterioration in site conditions.

Considering the diverse disaster site conditions, a system to support drainage pump installation was developed to ensure the use of existing drainage pumps even under snow-cover, rough road and other poor conditions, in order to achieve flexible site management and safe and efficient installation and removal of pumps.

As a result of examining records of drainage pump trucks dispatched to disaster sites in the past, as well as the results of interviews with operators, a self-propelled installation support system was selected as an effective means of transporting drainage pumps to and installing them in areas that require draining even in snow-cover or other sites with poor condition in winter.

After considering the basic performance and specifications necessary for the support system, a prototype was produced.

Then the performance of the prototype was verified and points that required improvement were identified by conducting operating, drainage and other tests at a disaster drill facility in summer and winter.

The operating tests were conducted basically on flat and sloped sites with different types of surfaces, such as asphalt, muddy, gravel, grassy and snow-covered surfaces. The drainage tests were conducted to monitor air suction during drainage, decline in drainage performance and other aspects.

The results of the performance tests were generally good in both summer and winter, and showed no significant problems.

While a certain degree of unsteadiness was observed while operating on slopes, it was considered possible to improve this by readjusting the weight balance.

On the whole, the system was high mobile and workable, and displayed sufficient performance. Since its operating and drainage performance in the performance tests was considered practical enough, it is planned to test the system during disaster drills and at other actual sites to verify its site applicability in the future.

(Contact: Machinery Technology Research Team, CERI)

Hindrance to construction work

- Peaty Soft Ground Countermeasure Manual released on the Website -

What is peaty soft ground? |

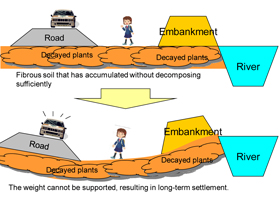

Settlement of a road on peaty soft ground |

Deep mixing method (case of mixing the lime or cement by machine) |

In Hokkaido, very weak ground known as peaty soft ground exists over an extensive area. Peat, which is produced by the gradual accumulation of dead plants that have not fully decomposed, is a type of ground unique to cold regions such as Hokkaido. Since the strength of peaty soft ground to support the weight of structures is extremely low, determining the safe height of, for example, a road or river embankment becomes a problem. It is also known that peat settles easily with a small load and the settlement continues for an extended period. As elevation or settlement of surrounding ground may also affect works, peaty soft ground has long been a problem for civil engineers.

CERI has been conducting research to develop technologies to construct safe civil engineering structures (e.g., road and river embankments) economically even on peaty soft ground. Based on many experiences and research results obtained over the years, CERI compiled the Peaty Soft Ground Countermeasure Manual, which contains strength evaluation and settlement prediction formulas with consideration to the specific properties of peat, applicability of various countermeasures to peaty ground, and a flowchart of the selection of countermeasures.

An example of a countermeasure included in the manual is the deep mixing method. Advantages of this method of chemically solidifying soft ground by mixing lime or cement into soil are relatively low vibration and noise levels.

The Peaty Soft Ground Countermeasure Manual published in March 2002 (by the then Civil Engineering Research Institute of Hokkaido) is now out of print. Since we have received requests from many engineers throughout Japan wishing to obtain the manual, we established a system to make the manual available by download free of charge from the CERI website from Mar. 1st, 2010.

* Download page (Japanese only): http://jiban.ceri.go.jp/pm/

(Contact: Geotechnical Research Team, CERI)