To extend the life of road pavement

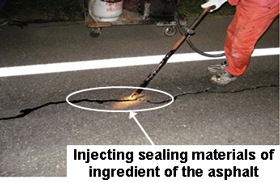

- Seal material injection method -

There are cracks in wheel running sections. |

Sealing material is injected to repair cracks. |

Road surface observation is conducted continuously after the repair. |

Since the flatness of a road surface is maintained when pavement is new and undamaged, drivers can drive smoothly and comfortably. They can also drive safely as the operability of the steering wheel is good. However, the damage and deterioration of pavement progresses gradually through use over the years. In particular, repetitive vehicle loads accelerate damage to pavement and causes cracking in pavement surface and rutting, a phenomenon in which running wheels make the road surface uneven. By repairing pavement before such conditions occur it is possible to delay the progress of damage and maintain the surface conditions for safe and comfortable driving for a longer period.

One method used to delay the progress of damage and extend the life of pavement is seal material injection method. This is a method of injecting seal of ingredient of the materials asphalt or resin into cracks in the road surface. Injection of the material is effective in reducing the extension of the length and width of cracks. While these effects delay the progress of damage to pavement and extend its life, there are many unknown matters, such as the actual amount of extension of the service life and the durability of seal materials.

Our team has been surveying cracks and the deterioration of injected sealing materials in actual roads and measuring the unevenness of road surface on a continuous basis. Based on the results of these surveys, we will contribute to extending the life of pavement by analyzing the progress of damage, the durability of sealing materials and life extending effect, and presenting the appropriate timing and methods for repairing damage.

(Contact: Road Maintenance Research Team, CERI)

Model testing of Sediment Ground

- Clarification of the Effectiveness of Rock Bolts -

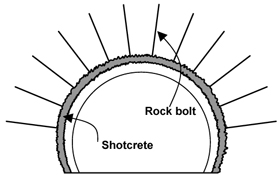

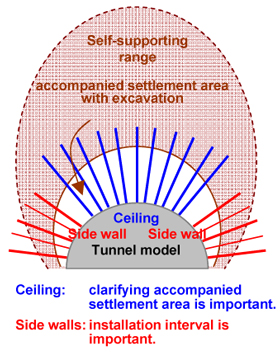

Figure 1. Tunnel Supporting Works |

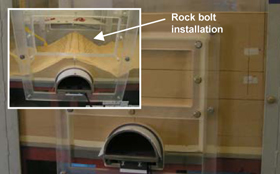

Photo 1. Installation of Rock Bolts |

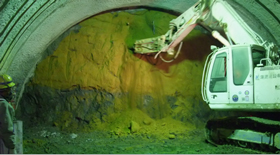

Photo 2. Sediment Ground Tunnel |

Photo 3. Test Apparatus |

Figure 2. Test Results |

Technological standards for the design and execution of road tunnels are set forward in The Technical Standards and Explanation for Road Tunnel (for Structures), a standard specifying mountain tunnel construction methods. It presents shotcrete thickness and rock bolt length and intervals etc. as standard combinations of supporting works (Fig. 1) such as shotcrete and rock bolts (Photo 1) which are members which support excavated spaces, and engineers engaged in the design and construction of road tunnels use it as a technical base. In recent years, the range of application of the mountain tunnel construction method has broadened as, for example, it is applied not only in mountains, but in the ground in which tunnels are excavated in cities etc. and other types of ground which is not easily stabilized. But standards stipulating generalized combinations of supporting works are intended mainly for use in hard ground in mountains, so in other situations, it is necessary to perform individual design with reference to the generalized combinations of supports.

One example of a case where individual design is necessary is a tunnel excavated in sediment ground (photo 2). In such a ground, many aspects of the effectiveness of rock bolts in particular are unclear, so model testing was done to research its dynamic mechanism. The testing was done using the test apparatus shown in Figure 3 and varying the rock bolt insertion range, length, and insertion interval etc. to study its impact on the tunnel model. The results revealed that in order to reduce the load of rock bolts acting on a tunnel in sediment ground, it is necessary that, as shown in Figure 2, rock bolts be long enough that the ceiling of the tunnel is self-supporting, or in other words, that the rock bolts reach a range where they do not move even when excavation is performed, and that on the side walls, the installation interval be a certain density.

Based on the results obtained from the testing, in the future, we wish

to verify the mechanism of supporting works in sediment ground and to propose

a concept of design which achieves more rational tunnel structures.

(Contact: Tunnel Research Team)