Genes and Civil Engineering

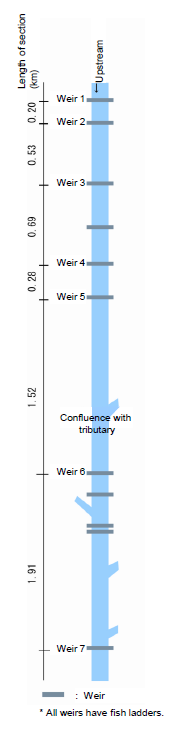

A fish ladder installed in a weir.

A fish ladder installed in a weir.

(Abukuma River)

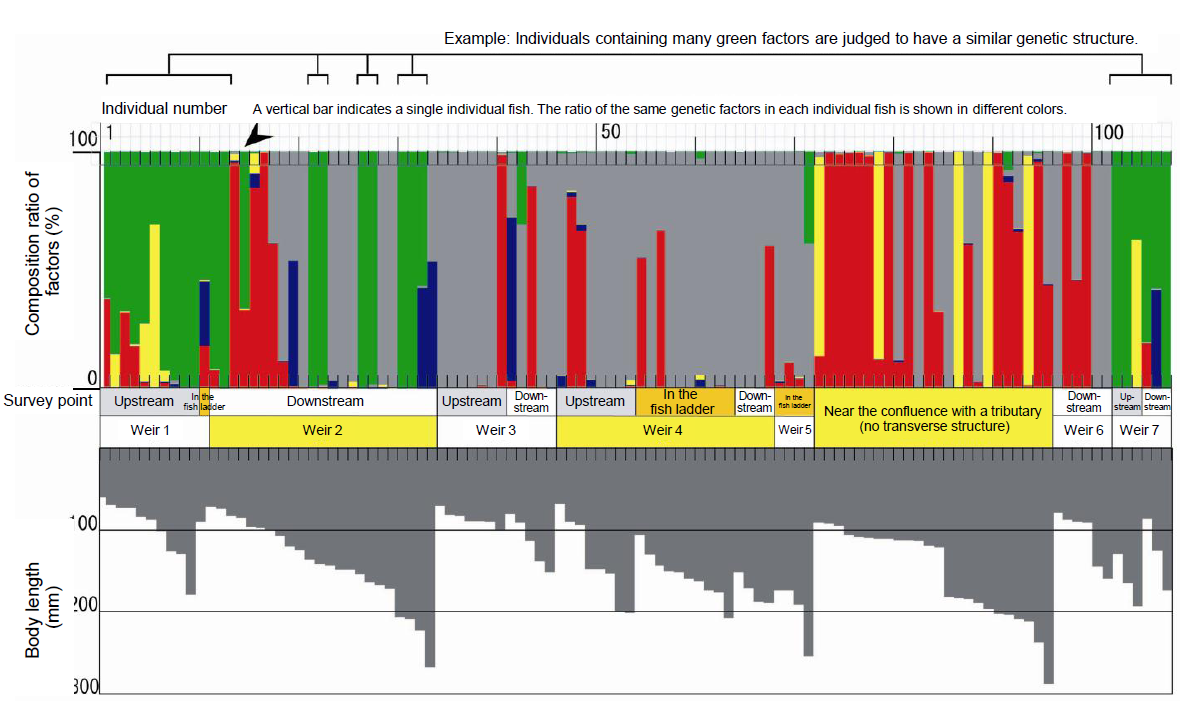

Relationship between the genetic

information of iwana trout and the weir.

the composition ratio of the genetic factors,

the information of the survey points,

and the body length of the fish.

A vertical bar in the composition ratio

of factors indicates a single individual,

and the colored bars indicate that

they share similar genetic factors.

All survey points are located along

the same section of river, and what

is shown on the left side is the most

upstream point. Take Weir 5 for example.

There are many individuals containing

yellow factors downstream of this weir,

but almost no such factors are seen

between Weirs 2 and 5. Likewise, almost

no green factors are seen between

Weirs 3 and 6. If fish were allowed to

freely swim through the weirs, there should

be no color distribution boundary.

The distribution of the individual fish’s

body length is largely divided into

three groups, and it is indicated that

groups demarcated by color boundaries

contain two or more generations.

This information consequently allows

us to assume the existence of some

factor (or factors) preventing the fish from

freely moving up and downstream

in the river around the areas Weir 5 and 6.

Genomics, or the study of genes, has recently become a very familiar field. These days, it may even be much easier for us to find articles about genes or related topics in newspapers and magazines for the general public than topics about civil engineering. Genetic technologies which have come to play an active role in the fields of medicine, pharmaceuticals and biology, are now gradually finding applications in the civil engineering field as well.

As you know, genes are part of the structure of almost all organisms. Genes differ from species to species but differences can also be observed between individuals. On the other hand, there are also genes which are common to mutually exchanging members of a group. By analyzing the information contained in those combinations of genes, we can detect, for example, whether or not there is any difference between groups, or whether genes from another group in a different area have been introduced. Such information is also useful in civil engineering.

Let’s examine rivers. There are a variety of structures constructed for various purposes along a river, including dams, weirs, and drop structures. When the design of such a structure does not allow fish to pass through freely, we construct a separate “fish ladder” (Fig. 1). Even when a fish ladder is present, however, the fish living in that area may be affected in various ways by the structure; for example, the fish may not be able to find the entrance to the fish ladder; they may be unable to successfully swim up the ladder; or sometimes, they may not feel like swimming up the ladder. If, for whatever reason, there is a long period where fish living in a dammed river are unable to pass freely, we may eventually find a difference in genetic information among the groups of fish.

Let us present a real-life example of the genetic information analysis of the river-dwelling iwana mountain trout. The survey area is a 6 km-long section of a river along which 11 weirs were constructed. All weirs have a fish pass (Fig. 2). DNA was extracted from the fins of iwana trout caught upstream and downstream of seven of those weirs (Weirs 1 to 7) and at the confluence of the river and its tributary. The DNA was then put through AFLP (amplified fragment length polymorphism) analysis, the results of which were further analyzed, and genetic similarities among the individual fish were categorized and assigned a color as shown in Fig. 3. This figure shows that there is a difference in genetic information between upstream and downstream groups of iwana trout for some of the weirs including Weir 5. It is therefore hypothesized that those weirs or other unknown factors in that area are preventing the fish from free passage.

As explained above, the use of genetic information allows us to obtain information on the relationship of the fish groups or individuals. When combined with the information available from previous survey methods, such as what age fish there are at any given area, we can have a more concrete idea of how these creatures utilize their habitat space, which then leads us to the development and implementation of more effective measures for preservation of the river environment.

(Contact: River Restoration Research Team)

A Study on Construction, Quality Control and Durability Testing of Concrete Structures

- Curing Conditions and Concrete Quality -

A shrinkage crack occurring during

concrete construction

Freeze-thaw test equipment

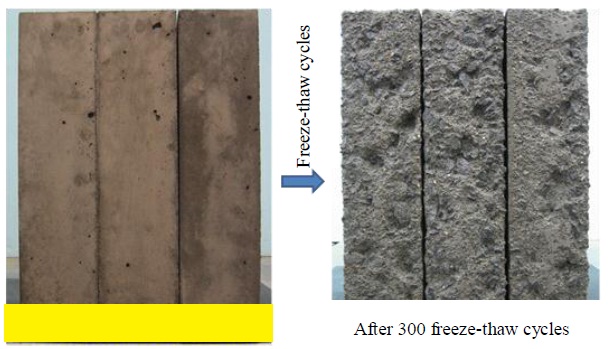

Concrete specimen with the surface delaminated

through freeze-thaw testing

Type-B Portland blast furnace cement

(W/C = 50%):

curing at 5℃, wet curing for 5 days

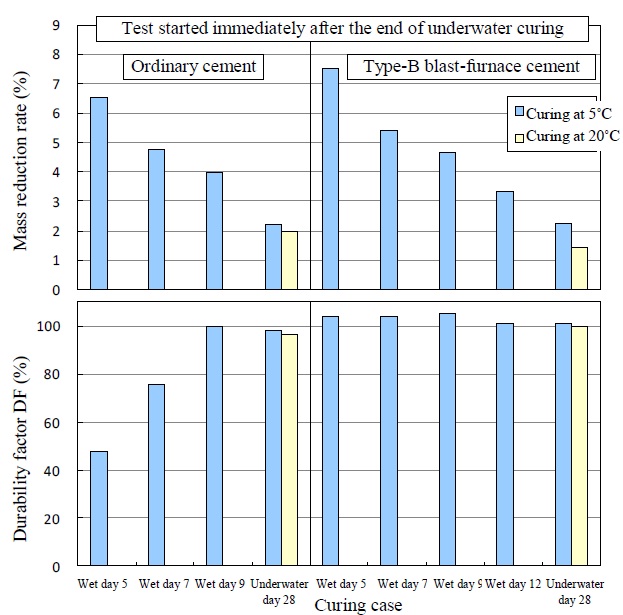

Freeze-thaw test results for concrete

subjected to different curing conditions

A variety of concrete structures are used in civil engineering work. Upon completion, such structures are inspected to confirm compliance with the predetermined specifications and the required level of quality. In addition to structural dimensions and appearance (surface finishing, presence of cracks, etc.), compressive strength and other properties are also checked. However, such inspections do not allow direct evaluation of structural resistance to phenomena that cause cracking and other forms of deterioration in concrete structures (i.e., the deterioration control function) as a result of changes in the volume of water penetrating them during freeze-thaw cycles in cold regions, nor do they clarify resistance to penetration by salt, which causes rusting of the reinforcing steel inside concrete structures. Accordingly, current completion inspections are inadequate for verifying the durability of concrete. In this regard, there is a need to establish testing techniques for the direct evaluation of concrete quality.

A series of studies was conducted jointly by the Concrete and Metallic Materials Research Team (Tsukuba) and the Materials Research Team (CERI) with their roles defined in an effort to develop a system for the evaluation of finished concrete quality. Among these works, a study performed by the Materials Research Team on how different curing conditions affect the freeze-thaw resistance of concrete is outlined here.

In the study, concrete solidified in different conditions of temperature, humidity and other variables was repeatedly subjected to freeze-thaw cycles at certain intervals to allow evaluation for the degree of deterioration in terms of the durability factor and the mass reduction rate based on measurement of the dynamic elastic modulus (which can be used to elucidate the properties of an object using vibrational waves: the harder and denser the object, the higher the value) and mass reduction stemming from concrete delamination. Sound concrete is known to have a higher durability factor. After repeated freeze-thaw cycles, concrete surface delamination occurs and mass decreases, thereby reducing the durability factor. In consideration of concrete construction in low-temperature environments, concrete specimens were prepared using ordinary Portland cement and Portland blast furnace cement (as common cement types) with low (5℃) and standard (20℃) curing temperatures on different days. Portland blast furnace cement is manufactured by replacing a certain amount of ordinary Portland cement with blast-furnace slag (a by-product of iron ore smelting), and is characterized by enhanced long-term strength and durability. A freeze-thaw test was performed on the specimens to evaluate their durability factors and other variables. The results showed that both types of concrete had low mass reduction rates when they had been cured for a long time. Ordinary Portland cement’s durability factor increased with the number of curing days, whereas Portland blast furnace cement showed high durability regardless of the duration of curing. Comparison of durability factor values and mass reduction rates between the curing temperatures of 20℃ and 5℃ after underwater curing showed no significant differences in test values attributable to different temperatures. These results confirmed that concrete durability is closely related to the length of the curing period and is influenced by the type of cement. In future work, we plan to develop a system for evaluating the quality of finished concrete using nondestructive testing equipment. Studies will also be continued to determine appropriate concrete construction methods suitable for various conditions based on the results of this study.

(Contact: Materials Research Team, CERI)

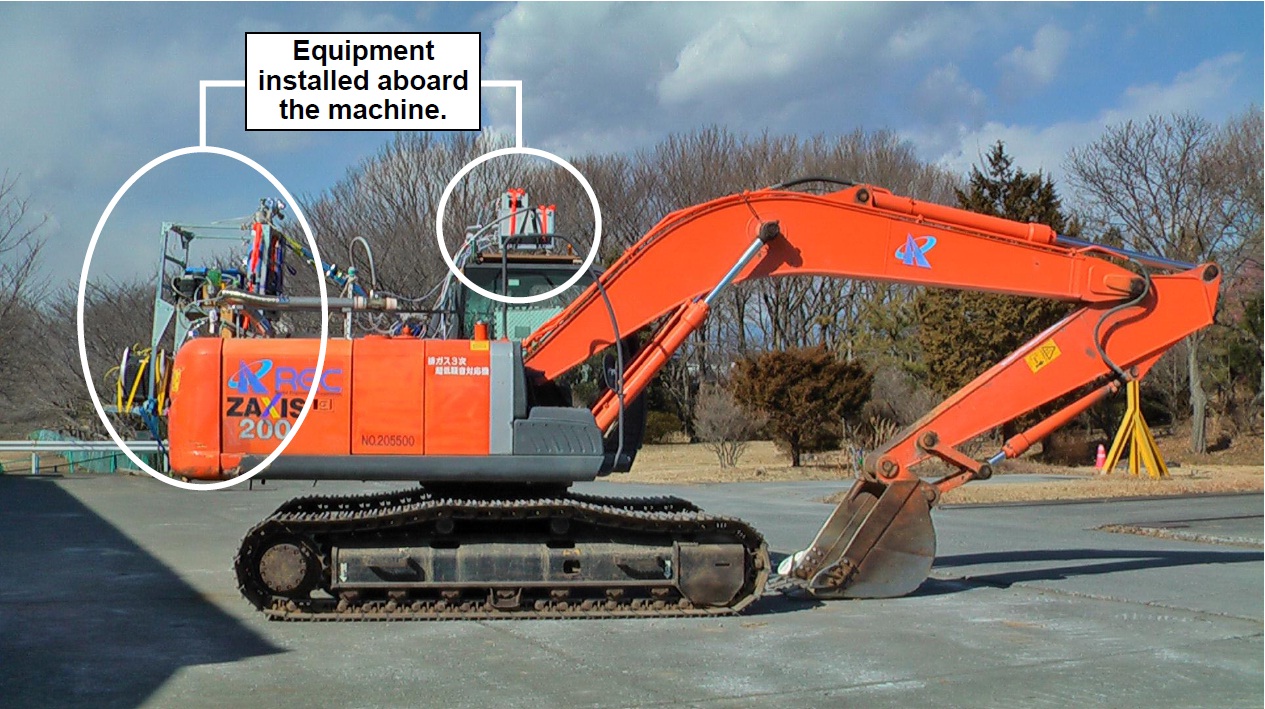

Measurement of Exhaust Gas of Construction Equipment While in Operation

A measuring device placed

on a hydraulic excavator.

An exhaust gas measuring device

installed on the operator’s cabin.

Gas emissions being measured

during excavation.

The vehicle emissions regulation came into effect in 2006 as a measure to control the emission of exhaust gas from construction equipment. The regulation stipulates that exhaust gas be measured using the predetermined testing method, and that levels of nitrogen oxides (NOx), hydrocarbon (HC), carbon monoxide (CO), particulate matter (PM), and black smoke in the exhaust gas do not exceed the predetermined standard level. Users of construction machinery are also obligated to use only machines with labels certifying that they meet the emission standard.

According to the specified exhaust gas testing method, exhaust gas from an engine should be measured using the designated testing system when the engine is in steady operation at eight patterns of engine speed and load, and the average should be calculated. Measurement for all engines should be made under the same coefficients related to the engine speed and loads, regardless of what machine the engine is installed in. But in reality, when a construction machine is actually used at a site, the engine speed and its load can vary depending both on the situation and also on the type of machine. Therefore, even if the machine has been certified, we cannot yet know for sure how much exhaust gas it generally emits under actual working conditions. In addition, the engine’s ability to reduce emissions can decrease with age, but removing the engine from the machine and testing the extent of deterioration according to the same method stipulated by the regulation is considered to be very costly.

Therefore, PWRI is working on a cost-effective method of measuring and evaluating the emission of gases using an on-board exhaust gas measuring device that makes on-site measurement possible. When measurement is made, every machine should be equipped with the measuring device, and because the machines are actually moving around at the work site, the attachment of such a device should not limit the proper functions of each machine (such as excavation, turning, or traveling). It is also necessary to consider, in the evaluation stage, possible deviation of the measured gas readings due to differences in loads and loading that varies from site to site or to the difference in operational skills of the vehicle operators.

As a solution to this challenge, under a program spanning from 2010 to 2012, we are now gathering data about exhaust gas emissions from hydraulic excavators, one of the representative pieces of construction equipment. Analyzing the results of the data will allow us to properly evaluate the amount of exhaust gas actually emitted from construction machines at work sites and to determine the degree of deterioration of the ability to reduce emissions. Recently, more machines have come to use biodiesel as fuel, and we will also be able to evaluate the gas emissions from those machines.

(Contact: Advanced Technology Research Team)