Diagnoses of the Soundness of Dams with Focus on Changes from Small Quakes

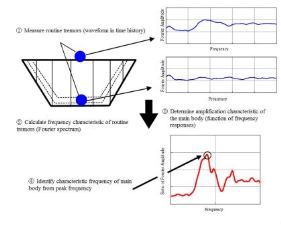

Fig. 1 Identification of Characteristic

Frequency by Measuring Routine Tremors

(click to enlarge)

Photo 1 Setting Device to

Measure Effects of Routine Tremors

1.Background to the Study

Because of the key role and due to its structural dimensions, dams are not easily replaced with an alternative facility nor readily reconstructed. Indeed, the main body of dams are designed and built to ensure the structure remain operable for extended years. While as of yet, there has been no case of serious safety concerns attributed to age deterioration of the main body of a dams, much of Japan's dams stock has now been exposed to wind, snow and other factors for long years since the start of operations. In light of the fact that there will be more aging and weathered dams in the future, there is a need to efficiently diagnose the structural soundness of dams. Also, in the aftermath of a major earthquake, it is imperative to move quickly confirm the safety of multiple dam sites. Accordingly, the obvious need here is for a means to efficiently diagnose the soundness of dams in an initial screening prior to detailed follow-up surveys. To that end, PWRI's Dam and Appurtenant Structures Research Team has undertaken to develop diagnoses techniques to detect changes in dam structural soundness, as a part of overall efforts to support longevity of a dam main body.

2.Ascertain Structural Condition of Dams by Measuring Effects of Minor Quakes

One technique to diagnose the soundness of the main dam body is to photograph the concrete with an infrared camera and identify spots of flaking or spalling by photo analysis. While this is a valid means of detecting flaking on the surface of the main body, it is less useful when trying to grasp conditions internal to the thick concrete. To confirm inner conditions, prevailing general practice is to core the concrete, making a hole in the main body or to test for presence of cracking by pumping water into the hole. These techniques are effective at pinpointing a spot which appears to be having a problem. However, these methods are not satisfactory when trying to ascertain the overall condition of the main body, especially the thick concrete layers.

At this point, we re-focused on the potential of methods of detecting the impacts of minor quakes on dam bodies. As shown in Figure 1 and Photo 1, these techniques measure the impacts of minor quakes, which can be called “routine tremors.” Impact is measured from a corridor at the bottom inside of the main dam and also from the top of dam. By comparing the response frequencies, we can identify one which can be easily amplified as the characteristic frequency of the main body.

A structure's characteristic frequency lowers when the soundness and structural hardness degrades from tiny cracks. This clearly offers the potential to detect changes in structural soundness by monitoring changes in characteristic frequency. The technique is being examined in other fields, such as diagnoses of degree of damage to buildings which otherwise appear undamaged by an earthquake. In the case of dams, chronologically accumulated data on characteristic frequencies known for separate parts of the main body can be used to identify areas where degradation is suspected of progressing. Then, detailed surveys can more easily follow. The accumulated data will be useful in conducting surveys and providing efficient countermeasures.

At present, the applicability of such techniques is being examined by conducting measurements and data analyses of concrete gravity dams. In hopes of adopting this method as a practice for early detection of deterioration, data gained from the experimental measurements of actual dams are being accumulated and analyzed.

(Contact: Dam and Appurtenant Structures Research Team)

Concrete for Low Carbon Society

Photo 1 (From left) Cement,

“Ground granulated blast-furnace slag”

and “Fly ash”(click to enlarge)

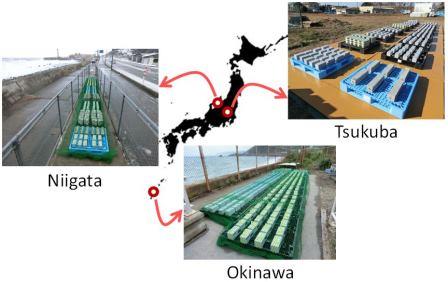

Photo 2 Outdoor Exposure Tests of

concrete specimens(click to enlarge)

Photo 3 Indoor accelerated test of

concrete specimens (To evaluate salt

permeation resistance of concrete)

(click to enlarge)

The concrete industry is trying to do its part to help solving global issues. Of particular note are recent studies into low-carbon concrete.

Concrete is a common construction material globally used, whose primary components are cement, water, sand and aggregate. The history of cement is long, as evidenced in the Egyptian pyramids and Roman aqueducts. Advances in technology came over in the interim, and over three billion tons of cement is annually manufactured. Today according to the U.S. Geological Survey (USGS), however, reports from the Intergovernmental Panel on Climate Change (IPCC) show that 5% of CO₂ emissions traceable to modern human economic activities are related to cement manufacturing. In other words, achieving practical low-carbon concrete with strength and durability comparable to existing products has the potential to significantly contribute to a low-carbon society.

What is the best way to produce low-carbon concrete with strength and durability comparable to existing products and while reducing CO₂ emissions? One suggestion is to replace cement components with by-products from other industries. Typical by-product materials include “ground granulated blast-furnace slag” obtained by quenching and pulverizing blast-furnace slag that is generated in smelting iron ore in the shaft furnaces of steel plants, and also “fly ash” residue from the combustion of coal at thermal (coal-fired) power plants (Photo 1). Although similar studies have been conducted in the past, using by-products primarily to reduce CO₂ emissions is a new concept emerged in the 21st century.

To best disseminate wider use of concrete mixed with quantities of by-product materials in public works, we must verify low-carbon concrete has sufficient strength and durability in real environmental conditions. We have fabricated numerous concrete specimens with different kinds and quantities of by-product materials, and use these in outdoor exposure tests at various locations throughout Japan (Photo 2). Regular inspections of these specimens provide long-term data on strength and durability. Also, we are working to develop indoor accelerated tests to enable quick evaluations of concrete durability in several hours (Photo 3), since outdoor exposure tests require several years to several decades of testing period for full results (Photo 3).

We are continuing to work on the best utilizations and technology development for practical applications of low-carbon concrete as a way to contribute to a low carbon society.

(Contact: Concrete and Metallic Materials Research Team)

Quality Rice Production in Peaty Paddy Fields

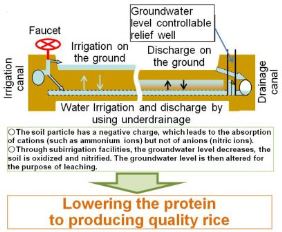

Fig. 1 Subirrigation system and the

concept behind quality rice production

(click to enlarge)

Photo 1 A test at a large paddy field

(click to enlarge)

Photo 2 Trial laboratory test device

for producing low-protein rice

(click to enlarge)

The Ishikari River Basin is widely distributed with peaty soil. Such soil is organic, prevalent in marshy areas and made from dead wet plants through accumulation without decomposition under the over-humid conditions. Most of this peatland is used for paddy fields. However, there is a concern about a decline in the number of rice farming households in the Ishikari River Basin. The development of larger paddy fields and subirrigation systems have been in progress for the purpose of saving labor by integrating separate farmlands for successor farmers. Figure 1 shows an overview of a subirrigation system.

To produce quality rice, the soil surface needs to be kept dry by draining the field in the mid season and the late season, i.e., lowering the groundwater level. The groundwater level is controlled by a subirrigation system. In the system, culverts are installed in the paddy fields. Attached to the culverts, a relief well controls the groundwater volume and discharges excess water to lower the water level. Then, water is added from the irrigation canal to the culverts, and the relief well retains water to raise the groundwater level and supply water from the underground to the plants.

The subirrigation system allows farmers to plant soybeans and wheat in paddy fields, to protect those crops from drought and to achieve stable production.

Under this system, farmers are also able to produce rice in some of their paddy fields while growing soybeans and wheat in other paddy fields. Accordingly, they will be able to separately schedule work duties and hours during busy farming seasons.

In producing delicious rice, the protein content of the rice must be lowered. This is done by preventing paddy rice from absorbing excessive amounts of nitrogen during the grain-filling period.

Nevertheless, rice that matures in paddy fields with peat tends to have a high protein content, because the rice absorbs the excess nitrogen generated by peat decomposition. Toward decreasing that protein content, the Rural Resources Conservation Research Team has been testing ways of removing excess nitrogen from the field. The team uses the subirrigation system to alter the groundwater level during the grain-filling period (Photo 1).

The team found from test results that altering the groundwater level during the grain-filling period reduces the amount of nitrogen around paddy roots, thereby reducing the rice's protein content.

The team plans to test several patterns of groundwater level alteration to study the changing soil nitrogen dynamics in the laboratory (Photo 2) and onsite. This will lead to the determination of the appropriate timing for alteration of the groundwater level toward producing lower-protein rice.

(Contact: Rural Resources Conservation Research Team, CERI)

Study on the Quality of Groundwater Emitted from Tunnels

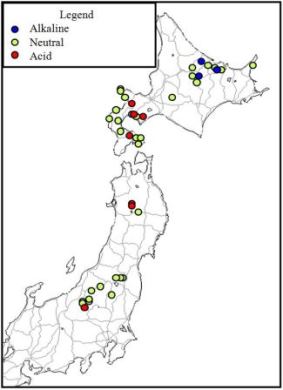

Fig. 1 pH distribution of groundwater

emitted from existing tunnels

Fig. 2 Sidewall deterioration caused

by acidic water

Hot, natural, spring-sourced groundwater that ranges from acid (pH1) to alkaline (pH11) is found throughout Japan. Groundwater from Tamagawa Onsen in Akita Prefecture has a pH of 1.3 whereas that of the former Horonai Mine in Hokkaido Prefecture has a pH of 1.7. Tunnel drillers sometimes encounter groundwater that is highly acid or alkaline. Figure 1 shows the distribution of groundwater pH emitted from existing tunnels in northern and eastern Japan. Groundwater with abnormal acidity/alkalinity is constantly discharged to rivers and the sea during and after tunnel construction. Nevertheless, the impact of such groundwater discharge on the surrounding environment is not known. In this study, we surveyed the pH, electroconductivity, oxidation reduction potential and trace elements of groundwater emitted from existing tunnels, in an attempt to determine the impact of the water on civil engineering structures and the surrounding environment.

Figure 2 is a photo of a tunnel's sidewall, from which acid water is emitted. Since its construction 50 years ago, acidic groundwater with a pH of 3.0 has eroded, dissolved and exfoliated the lined concrete. We found that such groundwater contains high concentrations of trace metals; for example, the calcium concentrations are triple that of mountain stream water, and the iron concentrations are 17 times that of stream water. As some sample concrete was found to have undergone dissolution from the groundwater, these metals are estimated to have been emitted from the concrete and steel support. We also detected toxic elements, including natural arsenic, lead and selenium, in the surveyed groundwater. These elements are considered to have been emitted from the bedrock behind the sidewall. Not only can acid water dissolve concrete and steel support, but it can also dissolve bedrock minerals.

In forthcoming studies, we will analyze the correlation between geological features and emitted water quality of tunnel rock mass toward verifying the impact of the emitted groundwater on management and maintenance and on the environment.

(Contact: Geological Hazards Research Team, CERI)