Long-term drainage performance and durability of underdrains with pumice as a filter on peat farmland confirmed: Verification of performance of underdrain using pumice as filter constructed in peat farmland

Cross-section of underdrain

constructed with pumice filter

Groundwater level survey at

an agricultural field installed with

underdrain with pumice filter

Peaty soil is widely distributed in Hokkaido. In cold regions, hygrophytes in moors do not decompose, because of the low temperatures; instead, they gradually accumulate to form peaty soil. Since such soil forms on land that was once more, the groundwater level is high. For peaty soil to be used as farmland, it is necessary to lower the groundwater level by draining the excess water.

For the purpose of lowering the groundwater level on farmland, drainage called underdrains has been installed. A common method of constructing underdrains in the past was to dig soil 1 meter deep linearly, lay drainage pipes called culverts there, and bury the site with the earth that had been excavated. In this method, however, the drainage performance can quickly deteriorate. Therefore underdrain construction using filter material has started to become a mainstream method. In this method, the dug part is buried not with the soil excavated from the site but with well-drained filter material before it is covered with the surface soil.

Since the method has recently become widespread, the durability of filter material was unknown, and it was necessary to clarify the durability of such material for the rational replacement of deteriorated underdrains with new ones.

The Civil Engineering Research Institute for Cold Region has been conducting regular investigations in order to determine the effective lifetime of underdrains that use as a filter material the pumice taken in region where coarse-grained volcanic ash has fallen. The results revealed that, 11 years after installation, the site is still sufficiently drained and the pumice has not been dissolved and lost or broken from the action of the highly acidic water that characterizes peat soil. The Civil Engineering Research Institute for Cold Region will continue its regular investigations at the same site in order to clarify the lifetime of pumice as a filter material and to formulate a technical guideline for the rational replacement of deteriorated underdrains with pumice filter with new ones.

(Contact: Rural Resources Conservation Research Team, Civil Engineering Research Institute for Cold Region)

Effective use of surplus soil from construction: The development of a cost-effective technology for disposing of naturally-occurring heavy metals

Photo 1 Rocks covered

with landfill liner

Photo 2 Serpentinite

Figure 1 Schematic of

the disposal technology

1. Challenges relating to the disposal of excavated soil containing naturally-occurring heavy metals

Civil engineering work can generate large quantities of soils containing naturally-occurring heavy metals, such as arsenic. The Soil Contamination Countermeasures Act, revised in 2010, stipulates that when such soils are disposed of, it should be wrapped in landfill liner (Photo 1) or carried outside to the controlled type landfill site.

The rocks containing natural heavy metals generated from tunnel construction sites are mostly over 2 mm in grain size. This means that methods for leaching experiments are unclear and it is not subject to The Soil Contamination Countermeasures Act. Nevertheless, environmentally measures are required in view of the leaching out of heavy metals, because excavated rocks can become finer by weathering. Another issue is that disposing of large amounts of rocks in accordance with The Soil Contamination Countermeasures Act incurs a high disposal cost.

2. Development of a cost-effective disposal technology for soils containing heavy metals generated from construction site

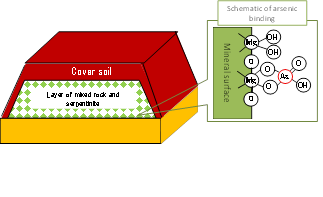

To solve these problems, a low-cost technology for the disposal of rocks containing heavy metals generated from tunnel construction sites is developed. In this technology, arsenic-containing rock is mixed with serpentinite (Photo 2).

Serpentinite contains brucite which is a magnesium hydroxide mineral. The brucite could be useful as material for the disposal of heavy metals, because arsenic strongly binds to brucite chemically. Experiments have been carried out in a laboratory and at road tunnel construction sites. The results were twofold. First, mixing serpentinite with arsenic-containing rock reduced arsenic elution by up to around 60%. Second, arsenic still strongly bound chemically to serpentinite that had become finer by weathering.

These results suggest that making embankment from mixed materials of excavated rock and serpentinite (Figure 1) will allow the low-cost disposal of rock generated during construction and the effective use of rock.

(Contact: Geological Hazards Research Team, Civil Engineering Research Institute for Cold Region)