Characteristics of Corrosion and Performance Degradation of Steel sheet-pile of Drainage Canals in Hokkaido

Background

The growth of crops is significantly influenced by the water environment of farmland, including the irrigation and drainage system. The improvement of drainage systems is an especially important issue in Hokkaido, as a large portion of its land consists of peatland and low-lying, ill-drained fields. Drainage canal development has been actively promoted as part of agricultural production infrastructure development efforts in the prefecture.

There is a variety of drainage canal protection methods. Among them, the steel sheet-pile method has been most frequently used for low-lying, weak ground (Photo 1). In national development projects in Hokkaido area alone, a total of approximately 100 km of canals has been constructed with this method. However, most of the piling was installed 20-30 years ago and has severely corroded, resulting in the collapse of the banks in the worst cases (Photo 2).

Therefore,it is an urgent issue to establish a method to diagnose and evaluate the status of corrosion of steel sheet-pile and performance degradation of drainage canals. This study examined the causes of corrosion and collapse of steel sheet-pile and performance degradation of drainage canals by closely studying the facilities in the area.

|  |

Corrosion Diagnosis of Steel sheet-pile

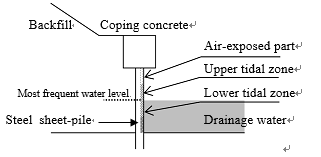

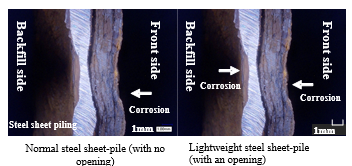

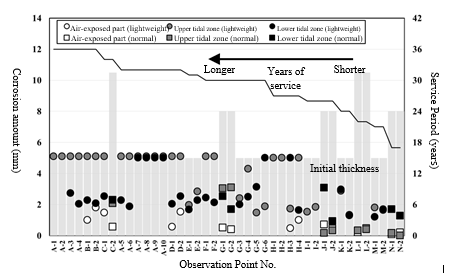

The amount of corrosion (decrease in thickness) of steel sheet-pile and the quality of drain water were measured for drainage canals constructed on weak peat grounds in Sorachi, Hokkaido (14 canals, 42 points). The structure of steel sheet-pile and an example of corrosion are shown in Figure 1 and Photo 3, respectively.

The results showed that the amount of corrosion is higher in older canals, with local severe corrosion also observed. It was also found that corrosion tends to be most severe and rapid in the upper tidal zone, followed by the lower tidal zone, and then the air-exposed part and that the corrosions rate were higher for lightweight steel sheet-pile (Figure 2). In terms of quality of drainage water, the corrosion rates were higher when the dissolved oxygen level was higher, the pH level was lower, the electric conductivity was higher, or the chloride ion concentration was higher.

|  |

| (lightweight: lightweight steel sheet-pile; normal: normal steel sheet-pile) |

Characteristics of Performance Degradation of Drainage Canals with Steel sheet-pile

Based on the results of observation and diagnosis of the steel sheet-pile, the performance degradation process of drainage canals seems to follow the following phases: [1] overall wet corrosion of the surface of steel sheet-pile and local corrosion due to potential differences; [2] development of floating rust; [3] fractures, cracks, and water leakage caused by loads applied on the thinned parts of piling; [4] further wet corrosion leading to damage and make holes; [5] loss of stability due to the suction of the backfill soil; and [6] leaning or collapse of the piling.

Such performance degradation of piling deteriorates the canal´s draining function and threatens the safety of the surroundings of the facility. It is necessary to establish clear performance requirements for components used for the repair, reinforcement, and renovation of piling (establishment of quality standards), and to improve the performance of components with future renovations.

In order to do so, we believe that the quantification of corrosion status of steel sheet-pile after its installment and a closer study of environmental factors that influence the corrosion process need to be conducted while keeping in mind unique phenomena in snowy cold regions.

(Contact:Irrigation and Drainage Facilities Research Team, CERI)