Developing a Technical Platform for Autonomous Construction

In recent years, the number of workers in Japan's construction industry has been shrinking as a result of the nation's declining birthrate and aging population. This is making it essential to raise construction work productivity so that the construction industry can be sustained. Given these circumstances, private companies and others are conducting research and development aimed at automating construction machinery to improve productivity. Currently, however, individual companies use machine communication and control systems that are based on their own signal rules. Such closed research and development not only leads to duplicated R&D but also makes it difficult for ambitious companies and universities to participate in R&D. To overcome this situation, the Advanced Technology Research Team is working to establish (1) unified signal rules (cooperative domain) and (2) autonomous construction technology platform.

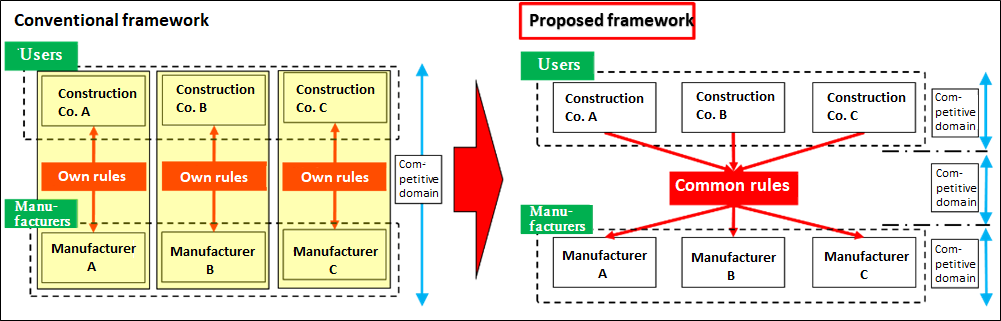

(1) Cooperative domain (Figure 1)

Establishing unified signal rules (cooperative domain) for controlling construction machinery will help prevent the duplication of machinery automation-oriented R&D. Additionally, because controlling machinery under common rules will become possible, it is anticipated that construction machinery users will be able to switch and combine various machines made by different manufacturers.

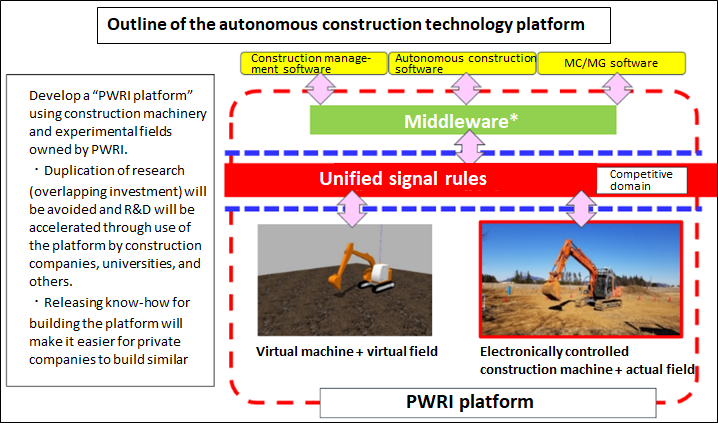

(2) Technical platform for autonomous construction (Figure 2)

Our team is developing a technological platform for conducting a series of autonomous construction operations based on unified signal rules. As is shown in Figure 2, the platform includes electronically controlled construction machinery and virtual construction machinery. The actual machines are controlled based on the cooperative domain that was established in (1) above. The functions and performance of the developed autonomous construction program can be verified through testing in a construction DX experimental field. At the same time, using simulations is effective in autonomous construction development from the standpoints of safety and development cost. R&D can be conducted efficiently and effectively by repeating tests in a virtual environment that reproduces electronically controlled construction machinery and the construction DX experimental field. This platform is applicable to everything from the R&D described above to actual construction. By making it open source, we hope to lower entry barriers and accelerate R&D for autonomous construction technology.

Looking ahead, we plan to establish a series of autonomous construction technologies based on the proposed scheme. We also plan to hold in-house demonstrations of autonomous construction as well as technical competitions (Photo 1). We will improve the specifications of the cooperative domain and the platform by exchanging opinions and making adjustments with concerned parties.

|

autonomous construction operations (excavating, loading, and transport) |

(Contact: Advanced Technology Research Team)

Development of Technology Applicable to Repair Work Using Accelerator for freeze protections

1. Background of the research

It is difficult to ensure the designed strength of civil engineering structures involving the use of concrete during cold seasons because the water in the concrete is frozen before reaching the strength of the concrete sufficiently. Therefore, the heat curing method is commonly adopted for construction work in cold seasons by providing heat with jet heaters or other devices, while installing temporary enclosures. However, in case the volume of the concrete cast is small, as in case of repair work, the time to install and remove the temporary enclosures and the cost of heat supply for curing pose problems.

Alternatively, it is suggested to use an accelerator for freeze protection for easy curing (Figure 1). An accelerator for freeze protection of concrete at a low temperature and is an admixture that slightly lowers the freezing temperature of concrete. However, thin members with a thickness of less than 40 cm are easily influenced by temperature and also freeze easily, and there are no regulations on accelerator for freeze protection. The prediction of strength generation based on maturity method is also unclear. We hereby introduce a case of coping with the problems at a construction site during research of the agent.

2. Technical consultation

At the construction site, under the limitations of taking the pre- and post-processes of the construction work into consideration, PC girders were cast with filling concrete of approximately 9 cm thick in early winter with the aim of ensuring compressive strength of 25 N/mm2 to make transversely fastening possible in the early stage of the work. Since the installation of temporary enclosures causes great losses both in terms of costs and time, the use of an accelerator for freeze protection was considered. However, use of the agent for thin members deviated from the applicable standards. It was therefore necessary to carefully examine whether strength could be secured only by easy poly tarps curing or not, among other conditions.

3. Application to thin members

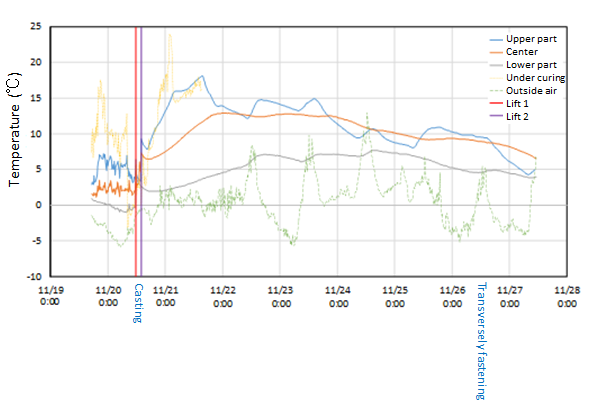

Temperature estimation was conducted using the temperature analysis software in advance to confirm whether the concrete temperature could be maintained above freezing point, even at the coldest parts, for 24 hours after casting of the concrete and whether compressive strength of 25 N/mm2 could be achieved by seven days later.

The existing guideline was referred to for the characteristic temperature values required for the analysis. The thermal conductivity ratio was set with the conditions of covering the girder surfaces with blue poly tarps and leaving the bottom surfaces open. Ten-day casting work in the middle of November was assumed, and for a total of 50 cases in the last five years, the girder surfaces were exposed to the outside temperature for 11 days before the casting date under the condition of heating the surface of the girders up to 15℃ between two days before casting and the date of casting. The research revealed that when the lowest temperature in 24 hours after casting reached -5℃ or lower, the temperature of part of the filling concrete would fall below 0℃. Heat-insulating materials were therefore set inside the molds, and a curing method of heating the girders from the upper parts, even after casting, was suggested to maintain the appropriate temperature (Figure 2).

4. Strength management using maturity method

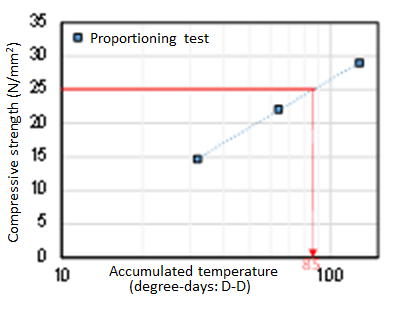

To determine the appropriate time to finish curing and to remove the molds of civil engineering structures using concrete under the cold environment, it is important to control the compressive strength at an early period of the concrete age. Since the time of strength generation of concrete to which an accelerator for freeze protection has been added was unclear, for the mixing test of this construction work, an accumulated temperature of 85 degree-days was considered as the achievement criteria when the required compressive strength of 25 N/mm2 was obtained under a curing temperature of 21℃ (Figure 3). In the actual construction work, compressive tests were also conducted on test pieces placed under the same condition as the construction site. The results revealed that even lower parts of the filling concrete of which the temperature was the lowest obtained a required strength of 85 degree-days until the date when transverse fastening was conducted on the 6th day after curing. Following later research, a strength prediction formula corresponding to the differences in the water-cement ratio and the amount of accelerator for freeze protection was proposed.

5. Application effects and future utilization

Although heat-supply curing was adopted at some parts of this construction site, the accelerator for freeze protection significantly reduces temporary construction work processes, cutting the total cost of 8.5 million yen and shortening the construction period by 23 days.

We propose to reflect these findings in the guidelines based on research results, and intend to contribute to productivity improvement at construction sites.

[References]

Yuta Ikeuchi, Hiroki Fujinoto, Ryo Hasegawa: Application of cold-resistant agent for winter construction of hollow concrete PC girders ? for a further cost-reduction effect ? The 63rd Hokkaido Development Technology Research Presentation, February 2020

(Contact: Materials Research Team, CERI)

Research on Watershed Environmental Management Technology for Stagnant Water Areas Focused on Lake Bottom Water

1. Introduction

In water areas where the flow of water slows down, such as lakes and dams, the phenomena of lowering of the water temperature of the lower part and accumulation of high salt concentration are witnessed, making turn-over of water between the upper and lower parts (stratification) difficult. The water quality in the lower parts deteriorates under these conditions because oxygen is consumed by decomposition of organic matter piled on the bottom of the lake as well as bottom sediment, causing anoxic conditions of water and eluting of nutrient salts such as phosphorus and nitrogen.

As a countermeasure, an aeration circulation device is introduced to send the air to the lower part of the water while promoting circulation of the upper and lower parts using bubbles. However, under special conditions of sea water mixed with the lake water, etc., highly toxic hydrogen sulfide may be generated in the lower parts of the water where oxygen is absent, causing the generation of blue tide, which causes fish mortality when mixed with the upper-layer water. In such a case, an aeration circulation device cannot be used. We hereby introduce the results of our research on water quality improvement technology for stagnant brackish lakes where the aforementioned condition tends to exist.

2. Oxygen supply test using an oxygen dissolution device (WEP)

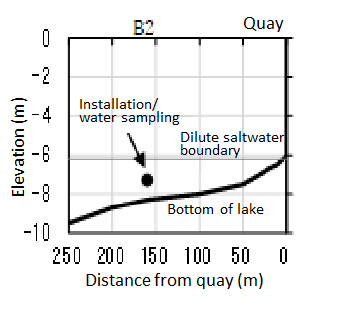

In Hokkaido, salt water from the sea forms the lower layer of lakes exposed to seawater run-up to form stratification, and thus promote a hypoxic lower layer. With this research, a device to supply oxygen directly to the hypoxic water mass over the lower layer was installed on a trial basis to verify the water quality improvement effects (Photo 1, Figure 1).

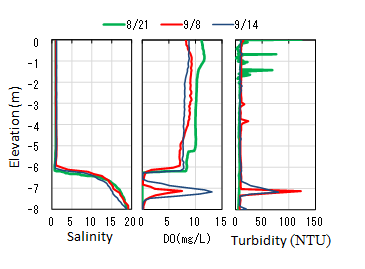

The air of which the oxygen concentration was raised up to 90% in the plant installed on the ground was pumped into the device set in the water before mixing the oxygen with the lake water in the device set in the water to discharge the water into the lake. Figure 2 indicates the vertical distribution of the water quality during operation of the devices. It shows that although dissolved oxygen (DO) rose and turbidity was found at the elevation where the water was discharged from the device, almost no changes in salinity were observed compared with the levels recorded before operation of the devices on August 21, and at a water depth of ?6 m, where the salt content suddenly changes, the levels did not change. It was thus confirmed that DO is only supplied to the lower layer and that there is no impact on the upper layer.

Reduction of the hydrogen sulfide concentration, and a phosphorus concentration-lowering effect were also confirmed. Since the effects spread vertically in the water, the device allowed improvement of water quality mainly by reducing the hydrogen sulfide. We intend to continue performing research to establish water quality improvement measures for water areas under similar conditions as those covered by this research.

the device |

|

supplying site (elevation where water is discharged from

the device: -7.5 m)

(Responsible persons: Koki Sugihara, Keiko Iwakura)

(Contact: Watershed Environmental Engineering Research Team, CERI)