Dynamic Avalanche Observation and UAV Surveys

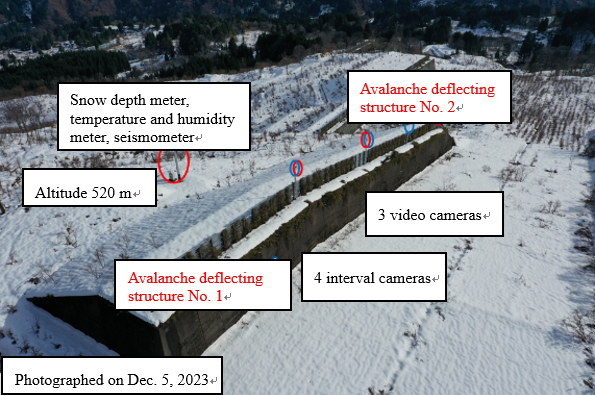

Photo 1. Observation instruments installed

at the Maseguchi area

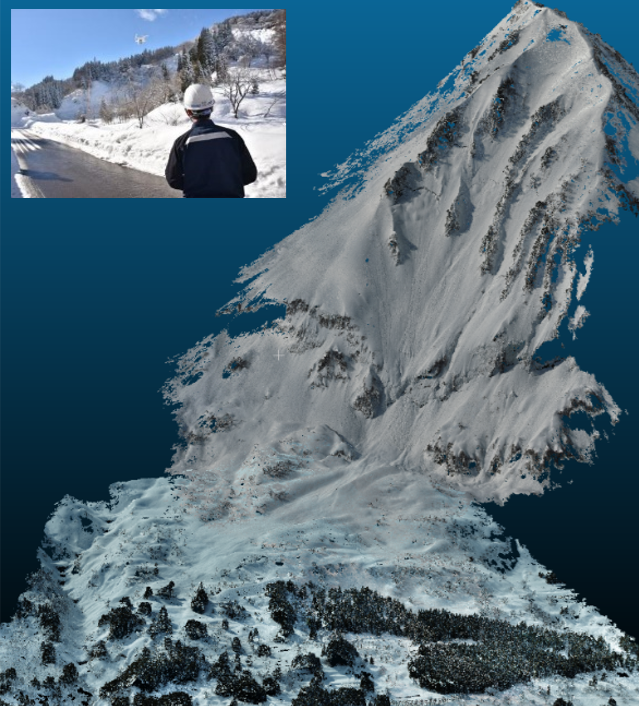

Figure 1. 3D topographic model of

the Maseguchi area

Japan is among the countries with the highest snowfall in the world. Nearly half of the country, primarily on the Sea of Japan side, is classified as a heavy snowfall area. Snowfall and accumulation significantly impact daily life in these regions, with avalanches posing a serious threat to settlements and road traffic.

It is possible to empirically determine avalanche hazard areas to some extent from the slope, height, and vegetation conditions at the site where avalanches have occurred in the past. However, snow conditions vary from time to time and are not uniform, making it difficult to predict whether or not an avalanche is likely to occur at a particular time and place and what the extent of the damage may be.

For this reason, PWRI has been researching methods to identify areas that are prone to avalanches based on snow accumulation and other conditions, and to estimate the area of impact. Here, we will introduce some of the methods.

Avalanches typically occur on snow-covered mountain slopes, complicating the collection of detailed data on the conditions that trigger them. Surveys of avalanches have traditionally relied on analyzing traces and snow cross-sections after the event. However, these traces and other information can change over time, impeding accurate analysis. Snow accumulation varies based on the weather conditions during and after snowfall, which in turn affects avalanche conditions. To better understand avalanche phenomena, it is crucial to observe slope conditions at the time of an avalanche and to analyze the site characteristics and flow process.

PWRI conducts avalanche surveys in the Maseguchi area of Itoigawa City, Niigata Prefecture, using video cameras and UAVs. Here, cameras capture the dynamics of avalanches from their onset to their downstream flow. Meteorological observation instruments and a seismograph are also installed to detect and confirm avalanche occurrences and to analyze snow cover conditions (Photo 1).

In the past, video recordings were used to determine the approximate location and flow path of avalanches. However, UAV surveys have become increasingly common in various fields in recent years. To analyze the snow cover and topographic characteristics of avalanche areas more thoroughly and efficiently, UAV photographs are now used to generate three-dimensional point cloud data of avalanche slopes for detailed investigation (Figure 1).

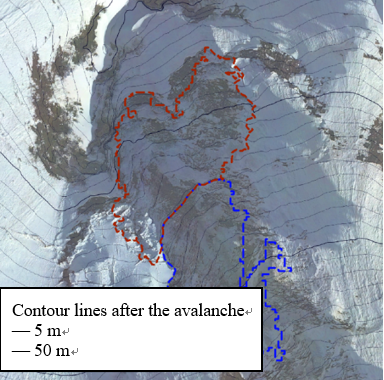

Figure 2 presents a topographic analysis of an avalanche that occurred in late Feb. 2023. Using a UAV, the precise locations of the avalanche's upper edge and lateral boundaries were captured in detail. Camera footage and seismographic recordings confirmed that this avalanche occurred as two distinct events. The behavior of the snowpack during the avalanche reveals that one section began moving first, followed by the mass of the snowpack around the upper cracks (Photo 2 (video)).

The detailed location of the avalanche area was identified through these surveys, allowing analysis of factors such as topography and snow cover conditions that determine the extent of the avalanche area. In the future, we aim to observe the dynamics of avalanches occurring under various conditions and to analyze the factors influencing the extent of avalanche areas, focusing on differences in snow cover and topography. Our research will also seek to predict the potential extent of avalanche damage at specific points in time.

|

|

|

(Contact : Snow Avalanche and Landslide Research Center)

Development of Technology for Using Volcanic Ash in Concrete

Concrete is a composite material made by mixing cement, water, gravel and sand together, and it is widely used as an inexpensive construction material that is easy to form. In recent years, however, global shortages of sand and massive carbon dioxide emissions from the cement production process have become problematic. The use of volcanic ash in concrete has been attracting attention as one way to solve these problems.

Volcanic ash is characterized by its ability to fill voids through what is called the pozzolanic reaction as the cement hydration reaction proceeds, resulting in dense concrete and improved long-term durability. Such concrete is found in ancient Roman ruins and was used in Japan as concrete for the breakwater of Otaru Port in the Meiji era (Photo-1). The use of volcanic ash has been limited by the fact that its properties vary greatly depending on the region from which it is mined and that it can be prone to low strength development at low temperatures. Nevertheless, using volcanic ash to replace part of the sand and cement can deal with sand shortages and reduce carbon dioxide emissions from cement production. Since volcanic ash is widely distributed and easily collectible in Japan, its use is expected to expand in the future, and in 2020, volcanic glass powder for use in concrete that is made by pulverizing volcanic ash was standardized in the Japanese Industrial Standards (JIS).

Our team is also working with other organizations to establish ways of using volcanic ash from various regions of Hokkaido as an admixture. Joint project has mainly investigated the use of volcanic ash as a substitute for sand. We fabricated large precast retaining walls and have conducted exposure tests in environments subjected to combined degradation from frost and salt damage. Ten years have passed since these blocks were placed in the harsh environment of the Sea of Japan, but they remain in sound condition (Photo-2).

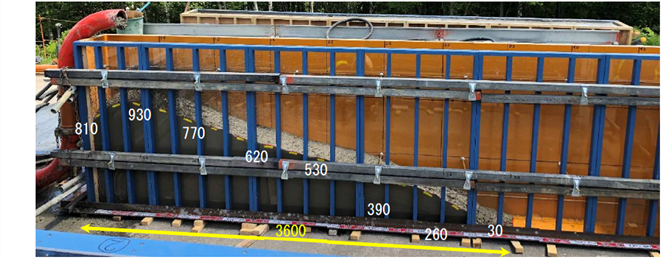

A recent example of volcanic materials in concrete is the use of a mix with volcanic glass powder to improve the surface quality of tunnel lining concrete. Since tunnel lining concrete is placed in one direction for at least 10 m from the pouring point to the edge of the formwork, the concrete must flow to the end of the formwork without segregating and must be dense and solid. Therefore, we prepared specimens using three different formulations, including one with volcanic glass powder, and we confirmed their workability and surface quality after hardening (Photo-3). The concrete with volcanic glass powder showed good flowability without segregation, and the specimens after hardening showed almost no spalling, surface air bubbles, color unevenness or placement joint between layers. In addition, the improvement over the standard mixure was confirmed in the evaluation scores.

In the future, we plan to propose a method for mixing and placing concrete utilizing volcanic ash and to compile that method as a manual.

|

(Contact: Materials Research Team, CERI)