Research on Strength Evaluation of Rockfill Materials for Cost Reduction of Rockfill Dam Construction

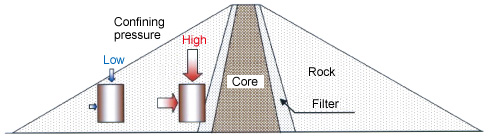

Rockfill dam is a large-scale earth structure that is built with core materials

to store reservoir, filter materials to prevent the piping of core materials,

and rock materials to secure the dam body stability against the sliding

failure. In recent years, the construction of such dams strongly requires

rationalization of design and execution, and cost reduction. Pressure applied

from the surrounding soil is called “confining pressure”; making

it possible to properly evaluate the strength of rock materials under low

confining pressure condition near the slope surface also makes it possible

to rationalize rockfill dam design and to reduce construction cost with

securing safety.

In laboratory tests using rock materials, such as surface sliding tests

and box shear tests, it was found that, when tests were conducted under

low confining pressure condition by changing the degree of compaction,

shear strength was greater than under the higher confining pressure condition.

Furthermore, a field test was performed at a rockfill dam under construction

to investigate the static angle of repose, which is the angle at which

stability is maintained without collapse and which is necessary to evaluate

shear strength under low confining pressure condition. As a result, it

was also found that actual compacted rock materials have large strength.

By advancing this kind of research, the Dam Structure Team is engaged in

daily study toward realizing reduced cost in dam construction.

(Contact: Dam Structure Research Team)

Safe Monitoring of Slope Movement!: Introduction to RE-MO-TE2 (Remote 2: Remote Monitoring Technology 2)

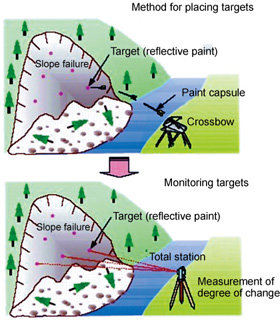

Slope failures, rock failures, and collapses at landslide ends can harm people working below them and damage houses and facilities. In order to predict such failures and collapses, it is important to monitor whether or not slopes and rocks are moving and, if they are, the degree to which they are moving. Effective methods for doing this include direct measurement of slope movement by placing extensometers on slopes or placement of targets directly on slopes and measuring them using survey equipment. However, entering areas prone to failure or collapse in order to place measuring devices and targets is extremely risky. Because of this, we joined hands with a private company to develop a monitoring technology that involves placing targets with high precision and from a distance and then using laser-equipped surveying devises, thereby making it unnecessary to directly enter slope areas. The following provides an outline of this technology.

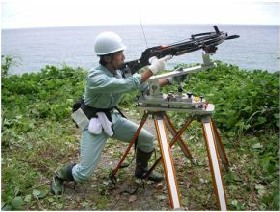

Do you know what a crossbow is? A crossbow is a bow (Western-style bow) that in recent years has been used as a shooting device in sporting events. The technology presented here uses this crossbow to shoot targets with high precision into slopes to be monitored.

The target is made of paint. A glass capsule containing the paint is attached to the end of an arrow that is shot from a crossbow. The glass capsule breaks open when the arrow hits the slope, thus forming the target. Into the paint are mixed extremely fine glass beads of 50μm; these beads improve the reflectivity of a laser that is shot from the surveying equipment (μ= 1/1 million).

We conducted an outdoor arrow-shooting test to send arrows into desired target locations. Through this test, we confirmed the trajectories that arrows fitted with glass capsules take.

This technology is being put to actual use in areas of unstable rock slopes that resulted from The Noto Hanto Earthquake in 2007 that occurred in March of last year as well as at slope failures at work sites.

(Contact: Landslide Research Team)