Non-destructive and Semi -destructive Testing of Concrete Structure - Inspection of Locations and Cover Depth of Reinforcing Bars and Concrete Strength

Important subjects related to the inspection of concrete structures are the locations and cover depth of the reinforcements in the concrete and the compressive strength of the concrete. Reinforcing bars (rebars) are corroded by salt attack damage unless they are arranged at an appropriate cover depth below the concrete surface. The building code revised after the Hanshin Awaji Earthquake in 1995 requires the additional installation of rebars in buildings.Accordingly, conventional large-scale destructive tests can damage these crowded rebars . When a construction work is completed, an inspection is conducted to check whether the building has been constructed according to the design, and whether the concrete has the required strength.

The inspection is generally conducted by means of non-destructive or semi-destructive testing so as to damage the structure as little as possible. It is also necessary to guarantee a certain level of measurement precision to achieve the purpose of the inspection. The Concrete and Metallic Materials Research Team is working on the research and development of inspection methods that can minimize the damage to the inspected structure and also ensure high measurement precision. Below we describe some of the inspection methods using non- or semi-destructive testing that we are developing recently.

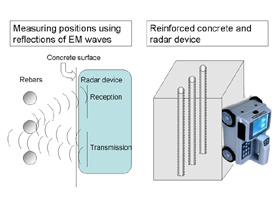

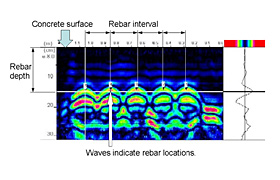

One of the non-destructive tests we are dealing with involves identifying the locations and cover depth of rebars using radar.

It is well known that radar is used to locate airplanes by utilizing reflected electromagnetic waves.

The same principle applies to locating rebars inside concrete. As the radar device scans across a concrete surface, it receives electromagnetic (EM) waves reflected from the rebars. The detected waveforms reveal the existence of foreign objects (that is, rebars) in the concrete. It also locates and cover depth the rebars by measuring the interval from the time EM waves emitted from the device to the time the device received its reflection. The important factor here is the speed of the EM waves. An airplane flies in the sky, and the speed of EM waves in air is the same as that of optical waves, or about 300,000 km/s. But the speed of EM waves in concrete changes depend on its water content. Therefore, we have been working on a the technique for calculating the speed of EM waves in concrete.

The next subject is mall-size cores, which are concrete samples for a mini-destructive tests. To measure the strength of concrete, cores are drilled from the target concrete for conducting compressive tests. Typical cores drilled for strength measurements are 100 mm in diameter and 200 mm in length. Recently, smaller cores (25 mm in diameter and 50 mm long), as seen in the center photograph, or much smaller ones (10 mm in diameter and 20 mm long), as seen in the photograph on the right, are used for strength measurements. The photograph on the left shows a 50 mm diameter core. Conventionally, 100 mm diameter cores are drilled from concrete. This illustrates smaller cores are advantageous to reduce damage on target concrete.

Important points about testing and practical procedures can be found on the relevant pages of the PWRI website.*

* For the locations and cover depth of rebars, access:http://www.pwri.go.jp/jpn/seika/conc-kaburi/conc-kaburi.html

For the concrete strength, access:http://www.pwri.go.jp/jpn/seika/conc-kyoudo/conc-kyoudo.html

(Contact: Concrete and Metallic Materials Research Team)

Protecting Kelp Beds

Photo 1(a): Place where sea urchins remained (June 1998) |

Photo 1(b): Place from which sea urchins were removed (June 1998) |

Photo 2: Growth of kelp on the artificial shaking substrates (June 2007) |

Kelp beds in the sea off Hokkaido are invaluable fisheries ground that produce over 80% of the kelp catch of the entire nation (according to the Hokkaido Agricultural, Forestry and Fisheries Statistical Yearbook 2006). Kelp beds have protective and nurturing functions since they serve as feeding grounds for shore grown life such as sea urchins and abalones, spawning grounds for fish, swarming grounds for shellfish, and refuges for young fish, thereby creating a rich marine environment. But the coralline flats, a phenomenon that deteriorates the kelps beds and whitens the ground, is occurring in the seawater of Hokkaido, and particularly in the rock reefs off southern Hokkaido along the Japan Sea. This is a serious issue facing Japan´s fisheries. Coralline flats cause a variety of problems, such as a reduction in kelp growth and catch, reduced sea urchin size, the disappearance of spawning grounds, and the eventual reduction of fish resources. All these phenomena cause a loss of rich marine life production.

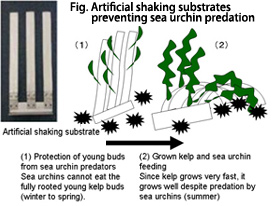

One major cause of coralline flats in the above waters is predation by the sea urchin strongylocentrotus nudus. When those sea urchins were experimentally removed from a withered seashore area, the kelp beds revived (Photographs 1 (a) (b)). When kelp grows to a certain size, it can grow faster than it is eaten and thus survive predation by sea urchins. But when kelp buds are still very young, these sea urchin predators completely consume the buds that germinated between winter and spring, thus completely eliminating the kelp in that area. The Fisheries Engineering Research Team has been engaged in research on artificial swinging material as a method for protecting young seaweed buds from sea urchins and helping form kelp beds. These substrates are flexible plates made of polyester cloth that are shaken by the waves. The material are finished with a urethane coating (Figure on the right) and are designed to prevent predation by sea urchins by shaking them off. Since sea urchins cannot access the plates because of their shaking motion, seaweed buds rooted or germinated on the plates can grow without being eaten, and the grown kelp droops under its own weight in the summer, creating an environment where sea urchins can feed without damaging the kelp.

We investigated the results obtained with this technique by installing artificial swinging material (Photograph 2) in the Era Fishing Port at Matsumae town, Hokkaido, which faces the Japan Sea. The young seaweeds germinated on the kelp in March, and seaweeds were seen growing on the artificial swinging material in June. The neighboring natural rock reefs and coastal structures where no material were installed remained coralline flats. The results of the investigation confirmed the beneficial effects of the artificial swinging material. We plan to perform various trials to determine whether we can apply this technique to other areas suffering from coralline flats.

(Contact: Fisheries Engineering Research Team, Civil Engineering Research Institute for Cold Region)