Technical Manual for Peaty Soft Ground

Peaty Soft Ground

Very soft soils called "peat" are widely seen in cold regions. Peat is an accumulation of decomposed wetland plants, such as reeds and sedges growing in swamps and lakes. With the low temperature and the high groundwater level, the layer of decomposed vegetation keeps growing thicker over the years, as the component plants are not fully decomposed. While broad peatlands are seen in the Hokkaido and Tohoku regions, small ones are also seen in all areas across Japan.

The thickness of a typical peat layer in Hokkaido is 3-5 m and there is often a soft clay layer underneath. It is not rare that the thickness of such clay layer is more than 20 m. We call this type of ground, which consists of a surface peat layer and an underlying soft clay layer, "peaty soft ground." In addition to the special characteristics of peat, the presence of a thick soft clay layer often makes it harder to deal with during construction.

Characteristics of Peat

In peat, plant fibers are entwined with one another and together create a sponge-like structure, just like the structure of luffa. Peat is a very unique type of soil that is by no means close to other ordinary soils. Peat contains a lot of voids which are filled with water. For this reason, even a little load on the soil can result in huge settlement. Moreover, settlement continues to occur over a long term. Since peat deposit is extremely soft, an embankment built on it may failure, as the ground lacks the strength to hold against the weight of the embankment.

Technical Manual for Peaty Soft Ground

Since peat soils have very unique characteristics as explained above, ordinary test and analysis methods do not work for them. To address this challenge, we published the Technical Manual for Peaty Soft Ground in March 2002, which explained the standard approaches for investigation, designing, and construction that we developed based on various experiences and study results accumulated so far.We further continued to work on research and technological development and revised the manual in March 2017, disseminating new technological information and the latest findings about antiseismic measures. The updated manual can be downloaded from our website (http://jiban.ceri.go.jp/pm/).

The Geotechnical Research Team will continue to promote studies on peaty soft ground and strive to disseminate useful technological information that serves the construction industry.

(Contact:Geotechnical Research Team, CERI)

Condition Monitoring and Diagnosis Technology for Pumping Equipment of Drainage Plant

1. Objectives

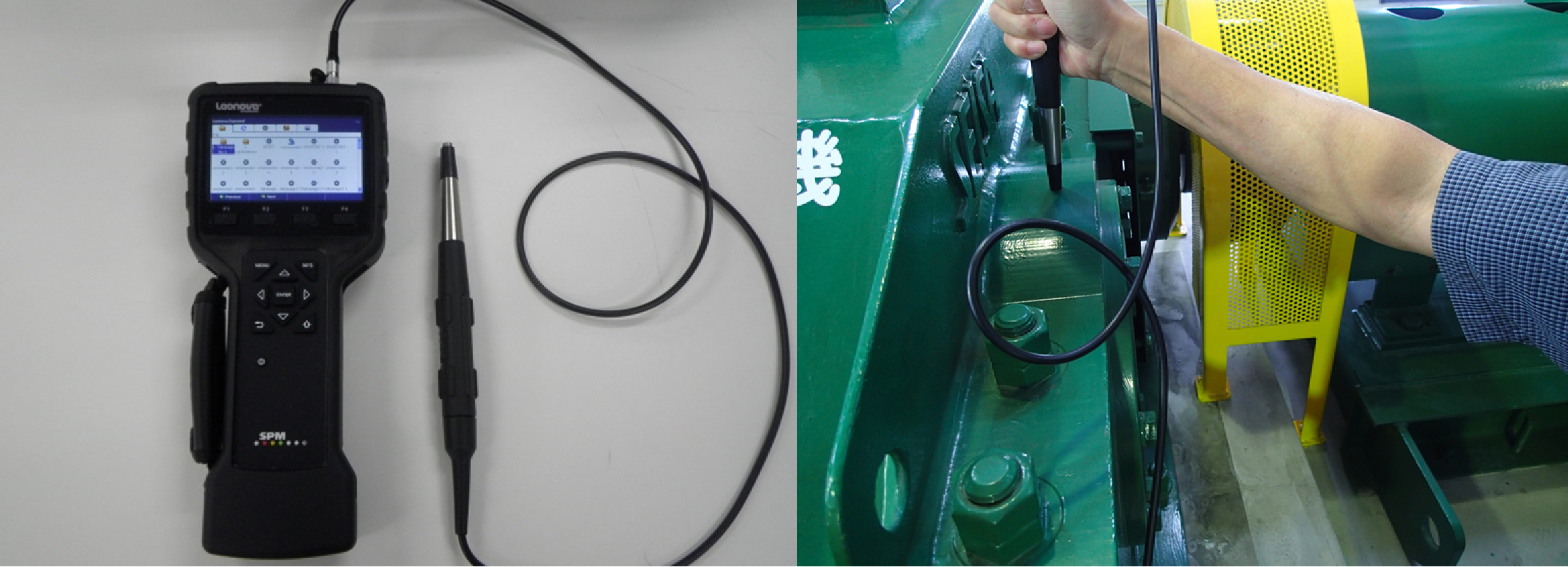

Pumping equipment of drainage plant form a very important aspect of flood control. It is required to make sure that these facilities can operate properly in emergencies. In this view, periodical maintenance has been conducted so far. However, in order to achieve efficient and effective maintenance with a limited budget, technology to monitor individual machines and accurately diagnose their state is required. In this article, we will share the results of the study on the feasibility of a diagnosis technology using the shock pulse method (SPM) for bearings of reduction gears, which are important pumping equipment of drainage plant that are difficult to monitor and diagnose (Photo 1).

2. Outline of the Study

When a reduction gear bearing is damaged, cyclical shock pulses are observed when the gear is rotating at a certain rate. By analyzing these shock pulses, the location of malfunction can be identified. However, it is difficult to diagnose the state of a reduction gear bearing with an accelerometer, because of the low rotation number and the effects of various vibrations occurring across the entire pumping equipment of drainage plant.

Therefore, we examined if the SPM, a condition monitoring and diagnosis method, could be used for reduction gear bearings at pumping equipment of drainage plant. The test was conducted with reduction gear bearings that have been used at pumping equipment of drainage plant in Hokkaido for more than 40 years (Photo 2).

3. Test Results

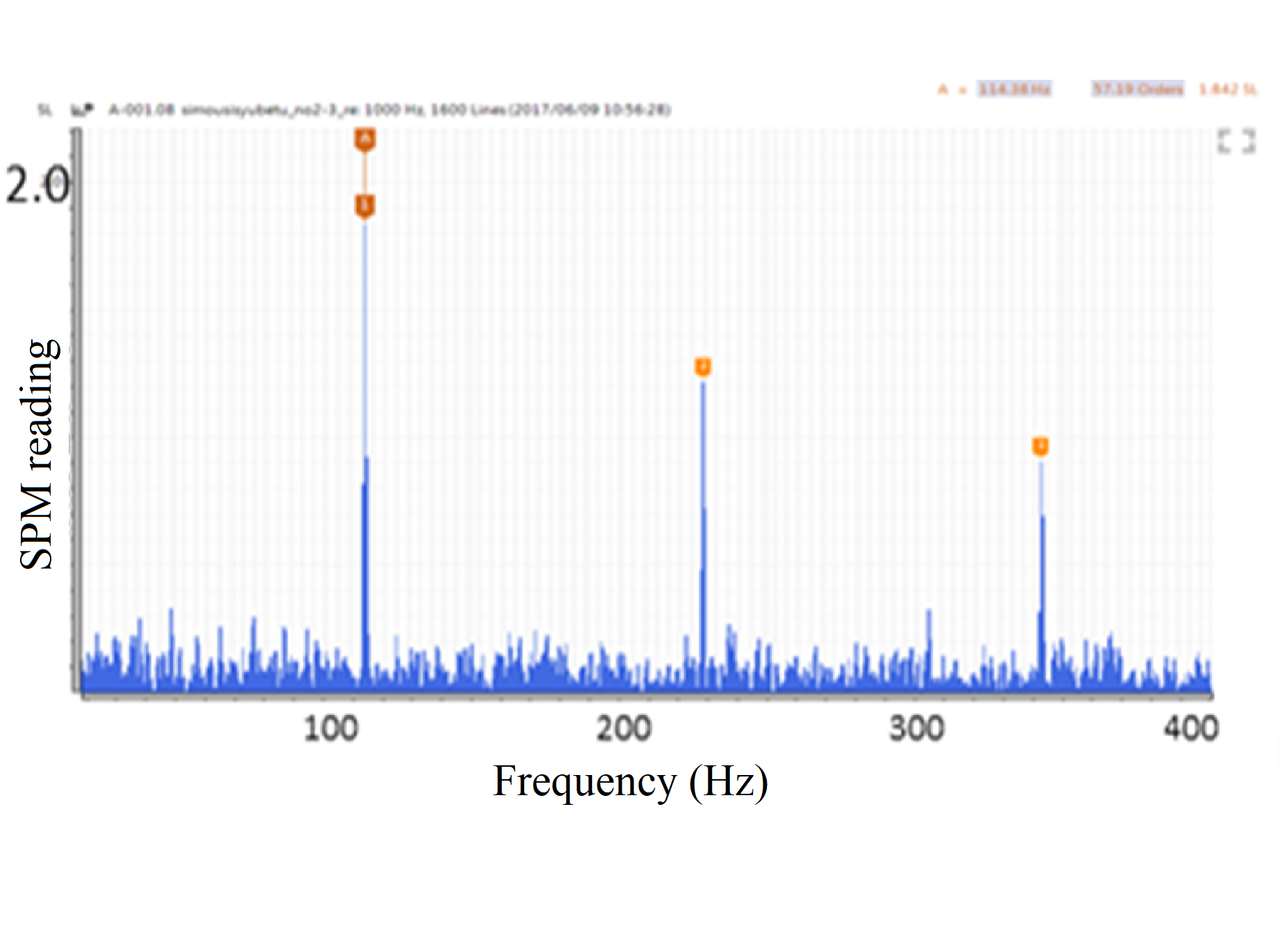

With the reduction gears used in the test, it was impossible to diagnose the state of the bearings with the traditional method using an accelerometer, due to the very low rotation rate of 150 rpm on the output side. However, as shown in Figure 1, characteristic frequencies were detected with measurements using the SPM, suggesting the possibility that this method can be used for the condition monitoring and diagnosis of the bearings.

In the future, we will examine a more comprehensive condition monitoring and diagnosis technology that combines various diagnosis methods, such as acoustic emission (AE) measurement, which deals with the elastic waves generated by the damaged parts, in addition to the SPM.

(Contact: Machinery Technology Research Team, CERI)