Introduction of Exposure Experiments to Frost Damage on Concrete under Deicing Salt Spraying Environment

|

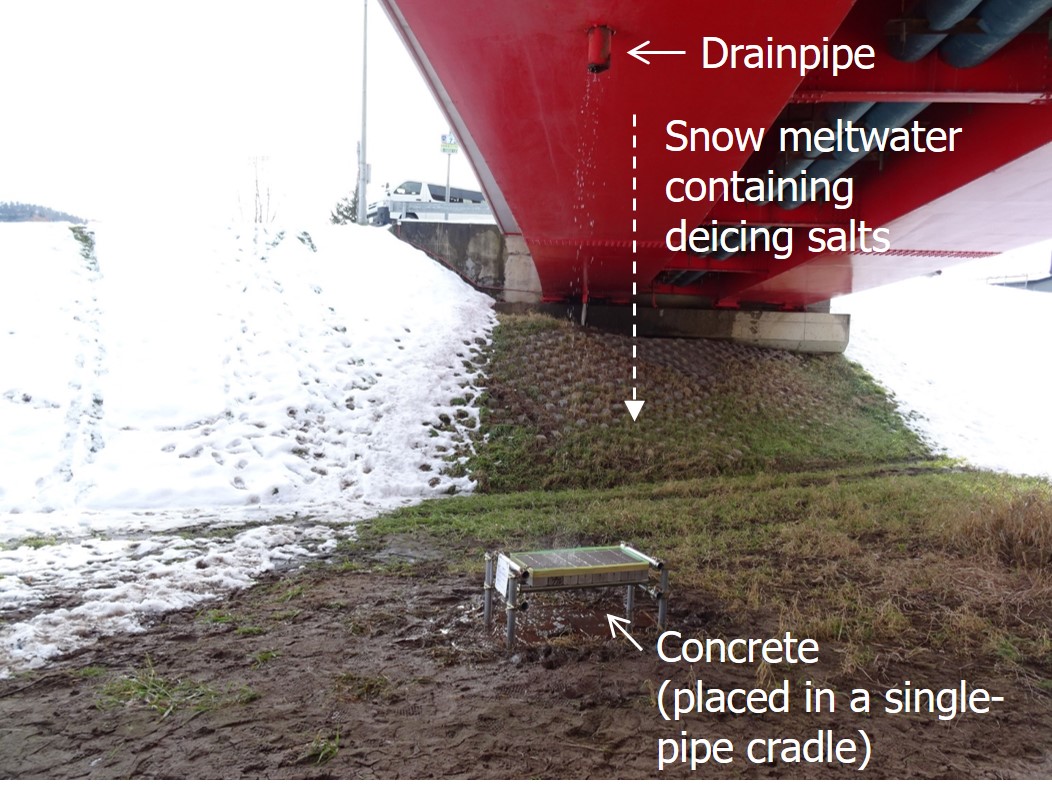

Deicing salts are spread in cold regions to secure driving safety in winter. It has been reported that the compound effects of deicing salt application and freeze-thaw can lead to frost damage in concrete structures on roads (Photo 1). The degree of damage to concrete is considered to be related to the amount of deicing salts sprayed and to their application method. However, the specific causal relationship between application and damage has not been clarified, so it is difficult to quantitatively estimate the degree of damage. For the purpose of understanding the causal relationship from the viewpoints of the degree of damage to concrete, the application method of deicing salts and environmental factors such as climate change, concrete exposure experiments have been conducted on highway bridges in Hokkaido where deicing salts are sprayed in winter.

|

Photo 2 shows the site of the concrete exposure experiments. Because concrete specimens placed on the road surface hinder vehicle travel, specimens were placed under the drainpipe of a highway bridge and were exposed to snow meltwater containing deicing salts flowing down from the opening of the drainpipe. The concrete exposure experiments were conducted at 20 national highway bridges in Hokkaido that were selected on the basis of the ease of work on site and in consideration of the need to cover various environments. The water-cement ratios of concrete were set at 45%, 55%, and 65%. Ordinary Portland cement or blast-furnace slag cement type B was used, and the air content was 4.5%. The concrete cast surface alone was exposed to snow meltwater, and the five other concrete faces were coated with epoxy resin for protection from snow meltwater. A mold 10mm high was placed on the cast surface to ensure that snow meltwater dripping down from the drainpipe would spread over the entire surface and that all specimens would be equally damaged.

|

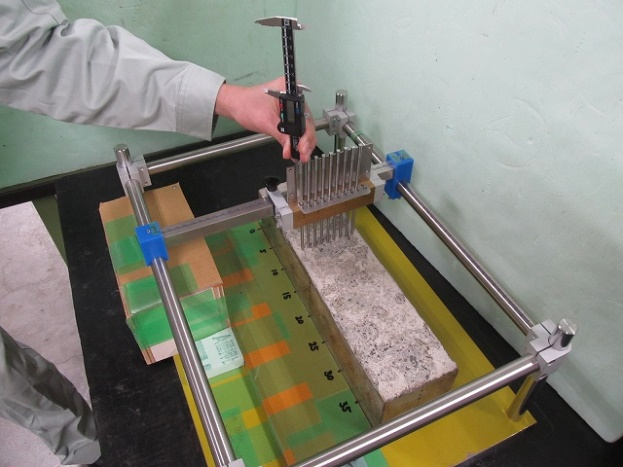

The depth of damage due to scaling after the specimens were exposed to snow meltwater in two winter seasons was measured. Scaling, a type of frost damage, is the local flaking or peeling of a finished surface. The measurement results are described below. Photo 3 shows how the scaling depth is measured. The measuring device was equipped with stainless steel rods that were 4mm in diameter. The pointed head of each rod was placed on the cast surface of the concrete specimen, and the depth of scaling was determined by measuring the length of the part of the pointed head that entered a void created by scaling. Nine stainless steel rods were placed at intervals of 6mm. Measurements were taken at 7 places located 50, 100, 150, 200, 250, 300, and 350mm from one end of the specimen. The average depth of scaling was calculated by using 63 measured values.

|

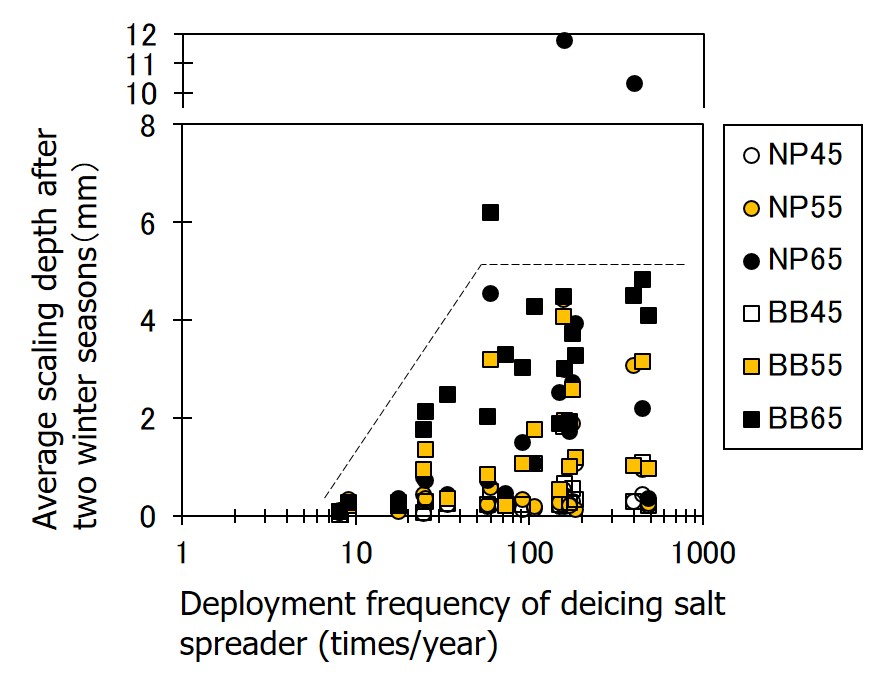

Figure 1 shows the relationship between the frequency of the operation of deicing salt spreader and the average scaling depth after two winter seasons. NP, BB, and the numerals in Figure 1 respectively refer to ordinary Portland cement, blast-furnace slag cement type B, and water-cement ratios. The deployment frequency of deicing salt spreader was counted on the following assumption: When a deicing salt spreader made a round trip to spread deicing salts on the outward leg and return leg, this was counted as one deployment. Regarding the highway bridges where deicing saltspreader was deployed fewer than 50 times/year, the average scaling depth was greater at greater frequency of spreading deployments. Under the condition that deicing salt spreader was deployed at least 50 times/year, there was no proportional relationship between the frequency of spreading deployment and the average scaling depth. It has been reported that scaling exacerbates when concrete is exposed to saltwater with a salinity of approximately 3%, although the progression of scaling also depends on the minimum temperatures [1]. It is also known that the salinity of snow meltwater on the road surface decreases quickly after deicing salts are sprayed [2]. Thus, it can be inferred that the salinity which promotes scaling tends to be maintained in the snow meltwater on the road surface where deicing salt spreader is deployed at least 50 times/year.

|

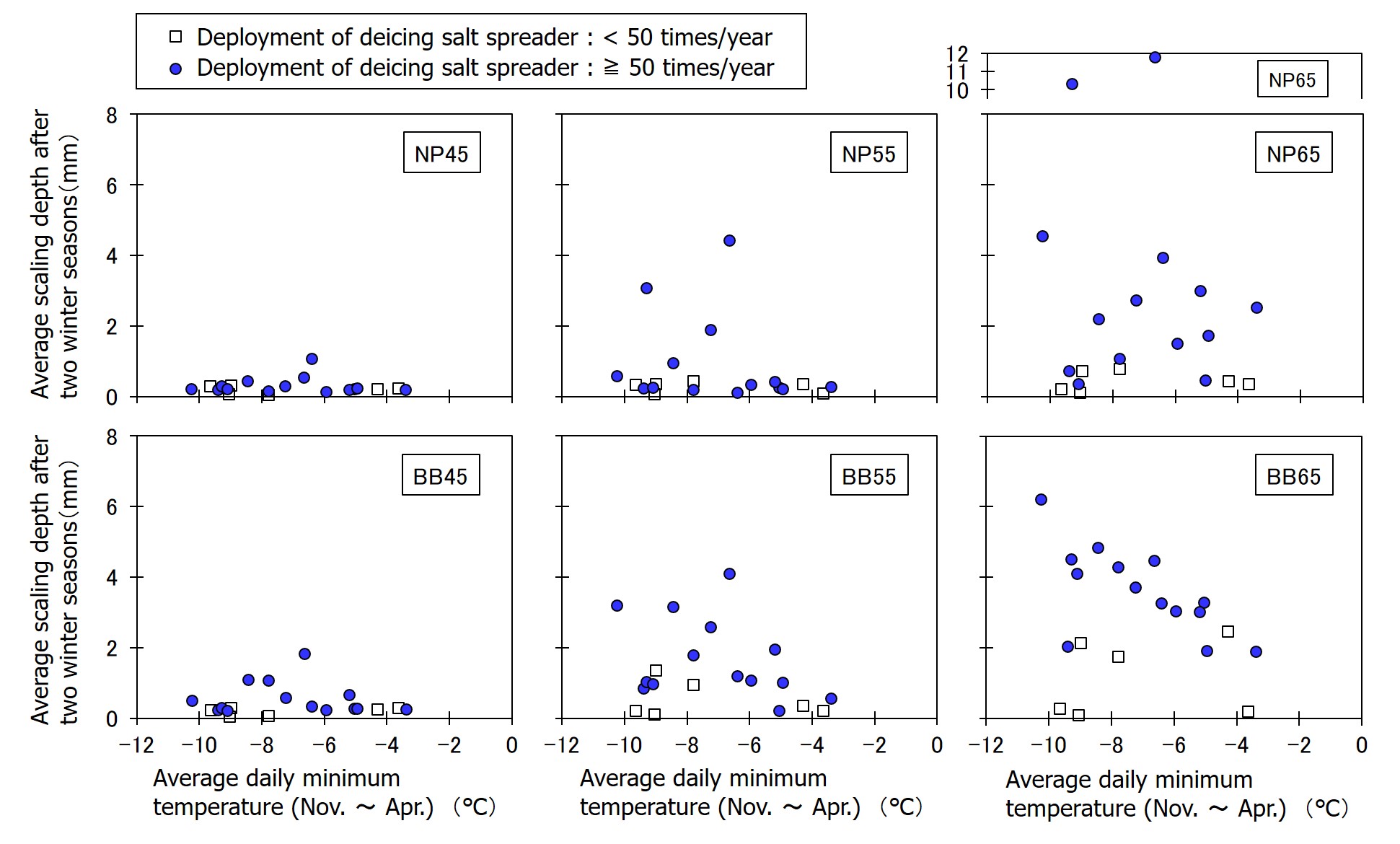

Figure 2 shows the relationship between the average daily minimum temperature (Nov. ~ Apr.) and the average scaling depth after two winter seasons. Scaling has tended to exacerbate in the concrete made with blast-furnace slag cement type B [3]. In the charts for the spreading frequency of at least 50 times /year, specimens of this type of concrete show greater average scaling depths in the regions where the daily minimum temperatures are lower than in other regions. The average scaling depth varies in the specimens of ordinary Portland cement. However, regarding some specimens, the values of the average scaling depth are also greater in the regions where the daily minimum temperatures are lower than in other regions.

These results indicate that the deployment frequency of deicing salt spreader and the daily minimum temperature during winter are environmental factors that serve as important indexes of scaling. This finding will help in the rational design of mix proportions that are tailored to different winter conditions and spreading methods, and will help in judgments of the need for deicing salt application. Because the results shown here are based on a two-year experiment, the Materials Research Team will continue research in order to accumulate data with the aim of establishing a frost damage prediction method.

[References]

[1] Verbeck, G. J. and Klieger, P.: Studies of Salt Scaling of Concrete, Highway Research Board, Bulletin, No.150, pp.1-13, 1957.

[2] Sano, H.: Automatic Deicing Agents Feeding System, Chapter 1 Research Report, Annual Report "Regional Technology" No.14, Construction Technology Research Department, Industrial Technology Center of Fukui Prefecture, pp.20-27, July 2001.

[3] Endoh, H., Taguchi, F., and Shimada, H.: Scaling Behavior of Concrete on Long-Term Freeze and Thaw by Salt Water, Journal of JSCE, No.725/V-58, pp.227-244, February 2003.

(Contact:Materials Research Team, CERI)

Development of re-sprouting control method for riparian forest stump using wood-decay fungi

The recent increase in the frequent storm disaster in Japan is reportedly associated with climate change. For this reason, river forest cutting and river channel excavation are being carried out throughout Japan to improve flood flow capacity. Generally, when riparian forests are cut down, the stumps are removed and disposed. It is said that this stump removal cost accounts for much of the construction cost. Of course, there is an option of leaving stumps when logging, but stumps can easily sprout and grow over 10m in 4 years. There are techniques to control sprouting from stumps, such as bark removal and herbicides, but they are expensive and impractical.

|

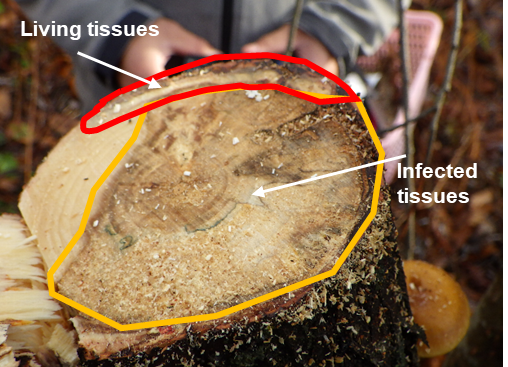

For this reason, the Watershed Environmental Engineering Research Team has begun research on methods to control the resprouting of stumps using wood-decay fungi. Wood-decay fungi have been classified in the kingdom Fungi according to Whitaker's theory of the Five Kingdoms system, but recently as a larger eukaryotic domain. Wood-decay fungi are the only organisms that can degrade wood lignin. Flammulina velutipes and Lentinula edodes, popular edible mushrooms in Japan, are also wood-decay fungi. Figure 1 shows the cross-section of the willow trunk, showing the state of infection of wood-decay fungi in the tissue. The Watershed Environmental Engineering Research Team investigates wood-decay fungi that grow naturally in riverside forests with the cooperation of Dr. Miyamoto of Hokkaido University Faculty of Agriculture, Ikeda River Office and Nayoro River Office. Through field surveys, we are trying to isolate wood-decay fungi that are unique to the region. Next, we plan to cultivate the isolated wood-decay fungi into spawning plugs, and inoculate this stump after logging. After that, the re-sprouting rate and stump degradation rate are measured to assess the effects of wood-decay fungi.

|

In addition, we are conducting an experiment to decompose woody debris with wood-decay fungi with teacher Okamoto of Obihiro Technical High School in Hokkaido and his students (Photo 1).

The research team gave them instructions on how to inoculate spawning plugs into woody debris, and provided general spawning plugs. High school students installed woody debris inoculated with wood-decay fungi on the riverbed near the high school. The research team and the students cooperate in planning experimental procedures and in observing the rate of decay. On November 18, 2019, with the consent of the Obihiro Department of Public Works Management, Hokkaido local Government, wood inoculated with wood-decay fungi including Flammulina velutipes was placed beside the Kikanko creek. Hopefully, we'll be able to see mushrooms growing on that woody debris this year.

(Contactt: Watershed Environmental Engineering Research Team, CERI)