Manual on the Use of a Diamond Cutter for Grinding Concrete Pavement (Draft)

1. Surface Grinding by Using a Diamond Cutter

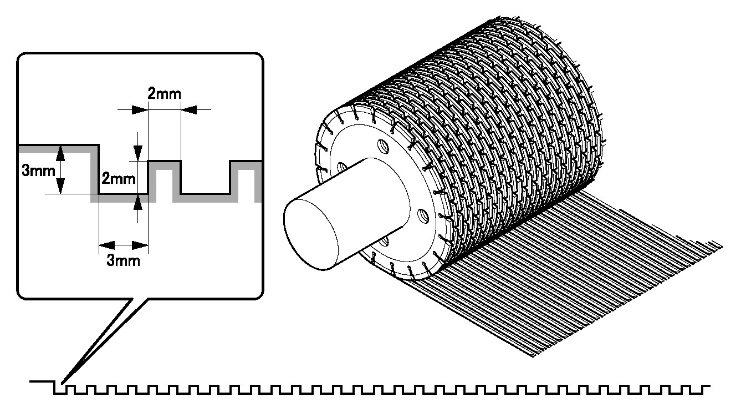

In surface grinding, diamond saw blades spaced at intervals of a few millimeters are used to shave off a thin (about 3mm-thick) top layer of concrete pavement in the longitudinal direction. The resulting unevenness helps to improve skid resistance and surface texture. Figure 1 shows the saw blades of a diamond cutter and the surface profile after grinding. By grinding the concrete pavement surface, the slippery surface layer is removed, and "fins" (Photo 1) are added to the coarse aggregate and cement mortar near the surface. The unevenness made up of fins created by grinding helps to improve skid resistance.

|

|

Conventionally, a broom finish is applied to the concrete pavement surface to prevent skidding by roughening the surface. However, because a broom finish creates unevenness on the mortar surface, the abrasion resistance is low and the unevenness is reduced by the polishing of tires on the pavement surface once the road enters service. Consequently, the road surface can become flat, smooth, shiny, and slippery over time. This grinding method is recommended for ameliorating such road surfaces.

2. Manual on the Use of a Diamond Cutter for Grinding Concrete Pavement (Draft)

The Civil Engineering Research Institute for Cold Region prepared the Manual on the Use of a Diamond Cutter for Grinding Concrete Pavement (Draft.) This technical document describes recommendations and points to note in implementing standard diamond grinding for the purpose of improving the skid resistance of concrete pavement in tunnels. This manual is freely downloadable from the website of the Road Maintenance Research Team

(http://www2.ceri.go.jp/jpn/iji/diamondcutter_manual/index.htm)

It is hoped that the manual will be helpful to many people.

(Contact:Road Maintenance Research Team, CERI)

Observation of the Variations in Water Pressure in an Agricultural Pipeline: Dynamic Water Pressure During an Earthquake

Research Background

Most irrigation water necessary for rice cultivation and dry-field farming is taken from rivers and sent down irrigation canals to agricultural land. Irrigation canals are concrete open channels or large-scale pipelines (Photo 1). In recent years, the share of the latter has been increasing because water is delivered more efficiently and water intake management is more easily when pipelines are used.

Most of these pipelines are installed underground. Because pipelines are filled with water and are under water pressure, water spout accidents occasionally occur. To avoid such accidents, pipelines are made so that pipes will not collapse under soil pressure or water pressure, and joints are made of a structure that does not come off at the joint between the pipes due to water pressure. However, it has been noted that a major earthquake can cause a significant change in water pressure in pipes. Such a change is likely to be a cause of breakage and detachment of pipes during an earthquake. This phenomenon has not been thoroughly investigated.

The Irrigation and Drainage Facilities Research Team has been conducting research toward understanding the mechanism of the changes in water pressure in pipes-i.e., the dynamic water pressure-during an earthquake.

Observation of Dynamic Water Pressure During an Earthquake

Dynamic water pressure develops at closed ends, curved sections, T-junctions, reducer joints, and other sections where the shape of a pipeline containing water changes. Because pipes at curved sections tend to move outward under water pressure, pipes at such sections tend to disconnect more easily with increases in water pressure. Additionally, dynamic water pressure develops at multiple sections where the pipeline shape changes, and water pressure waves propagate upstream and downstream, overlap with each other, and are eventually amplified. Thus, high water pressure can develop at unexpected sections of the pipeline some time after an earthquake, causing the breakage and disconnection of pipes.

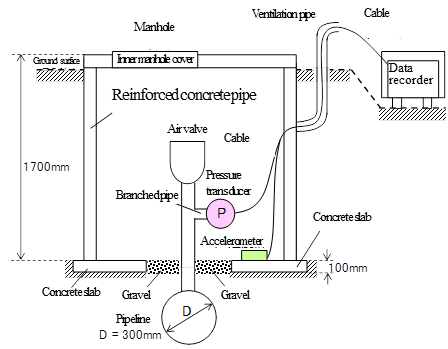

The Irrigation and Drainage Facilities Research Team has observation points at two pipelines in the Tokachi district of Hokkaido that were constructed under the National Irrigation and Drainage Project and are currently in use. The facilities (Figure 1) have been continuously used for simultaneous detailed observations of pipeline shaking and the changes in the water pressure in those pipelines. In the past, dynamic water pressure was observed in connection with two earthquakes with seismic intensities of 4, four earthquakes with seismic intensities of 3, and eleven earthquakes with seismic intensities of 2. Data were collected and analyzed.

and the dynamic water pressure during

an earthquake (observation result)

Observation Results

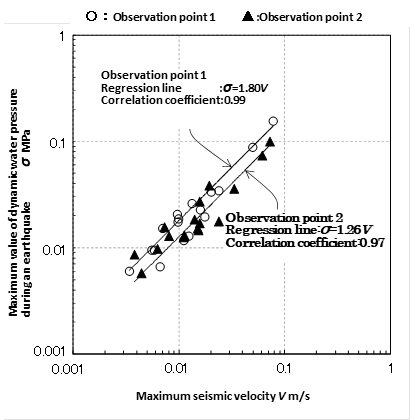

A positive correlation was confirmed between the maximum horizontal seismic velocity and the maximum value of dynamic water pressure during the earthquake (Figure 2.) In other words, with respect to the observation points, seismic intensities and how to swing can be used to predict how high the dynamic water pressure will be. This finding will help in the design of earthquake-proof, low-risk pipelines. However, because pressure waves develop and amplify at many parts of an entire pipeline during an earthquake, the magnitude of dynamic water pressure at each pipeline sections where dynamic water pressure is developed cannot be predicted. It is necessary to continue analysis by comparing mechanisms of pressure wave generation with measurement data.

(Contact:Irrigation and Drainage Facilities Research Team, CERI)