Protecting Bridges in Japan

Research on Diagnostic Techniques for Existing Concrete Structure

Corrosion of reinforcing steels in concrete |

Half-cell potential measurement |

Swedish National Road Agency |

In Japan, numerous civil engineering structures, many during the high economic growth period, have already been constructed, and there is a concern that they will rapidly age in the future. In future infrastructure improvement, how to efficiently maintain structures will be a very important point.

Concrete structures resist loads (for example, the load caused by vehicle

motion and earthquakes) with a combination of concrete and reinforcing

steels. However, concrete structures for which a long period of time has

passed since construction may have corroded reinforcing steels, reducing

their load carrying capacity. For this reason, there has been strong demand

for the establishment of nondestructive diagnostic techniques for evaluating

corrosion risk of reinforcing steels in concrete. The Structure Management

Technology Team of PWRI focused on a nondestructive inspection technique

called the "half-cell potential measurement" and studied how

to utilize this technique in the field. Half-cell potential measurement,

which allows inspection with simple equipment, has raised strong expectation

for practical applications. In this research, it has been suggested to

use the half-cell potential measurement in actual concrete structures.

We made a presentation at the Workshop on Road Science and Technology in Sweden to disseminate our research results. This Workshop has been held in alternate years for the exchanging of opinions on technological development in the field of road science in Japan and Sweden. The half-cell potential measurement is being researched outside Japan as well and the Workshop provided a good opportunity to exchange opinions on the issues to be solved for putting the method to practical use.

Regular diagnoses to maintain a sound, healthy condition are just as essential for civil engineering structures as they are for our bodies. We hope that the results of this research serve a useful purpose in maintaining concrete structures.

(Contact: Structure Management Technology Team)

Protecting Bridges in Japan

Research on the Improvement of Fatigue Resistance of Orthotropic Steel

Decks

|

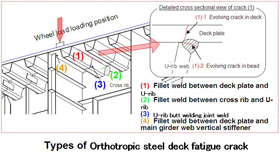

Types of steel plate deck fatigue crack (click to enlarge) |

Example of damage to pavement caused by fatigue of orthotropic steel deck |

Testing by making a model of the partial structure |

Wheel running test with actual-size test specimen of orthotropic steel deck |

Orthotropic steel deck is a type of bridge deck made of steel plates assembled together. Although, reinforced concrete are used as bridge decks, generally, orthotropic steel decks, which are lighter than concrete decks, are often used for long-span bridges and viaducts in urban area which are subjected to topographical conditions or other factors.

Bridge decks are covered with pavement, which vehicles travel upon. Dump truck, trailer, and other heavy vehicle travel cause fatigue to accumulate little by little. Needless to say, the accumulation of such fatigue does not compromise the safety of most bridges. On bridges where an extremely large number of heavy vehicles travel, however, in recent years there have been several observed cases of deck damage due to fatigue.

Fatigue of orthotropic steel decks may occur in locations that do not allow easy discovery of the precursors or progression thereof. The photo shows an example of fatigue crack in an orthotropic steel deck found by a check after a deformation was spotted in the pavement. We must avoid situations in which a crack is generated without being noticed and, when found, unevenness on the road surface is hampering the running of vehicles.

The Bridge Research Team, Structures Research Group of PWRI has been conducting research on the improvement of the fatigue durability of orthotropic steel decks. The content of the research includes the establishment of inspection methods for fatigue cracks, identification of the mechanism of fatigue crack generation, development of repair and retrofit methods for orthotropic steel deck with cracks, and the establishment of methods to design orthotropic steel decks resistant to fatigue cracks.

There are several types of fatigue cracks to study, as shown in the figure. Of these, fatigue cracks generated at the root of fillet weld between the deck plate and U-rib have been investigated first because the crack is difficult to be detected during its propagation. The photo shows a wheel running test being conducted using an actual-size test specimen to find out how fatigue cracks are generated. This test successfully reproduced fatigue cracks similar to those generated in an actual bridge. A technique of mitigating the local force on a steel deck plate by replacing asphalt pavement with the harder concrete pavement is being studied as a method of repair/reinforcement.

The Bridge Research Team will continue research to contribute to the safe, comfortable driving of vehicles running on orthotropic steel decks.

(Contact: Bridge Research Team)