Prevent liquefaction-caused riverbank settlement

A riverbank is a structure that prevents river water from entering protected lowlands and is designed to be higher than High Water Levels. However, when an earthquake occurs, the riverbank may settle. If it becomes lower than the river water level, river water enters the lowland, which has been damaged by the earthquake, thereby potentially causing second disaster. Through past experiences, we have figured out that most cases of significant riverbank settlement are caused by liquefaction of the ground under the bank. In order to prevent a second disaster from being caused by post-earthquake flooding, we need to take measures to control riverbank settlement caused by liquefaction.

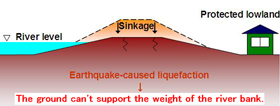

When the riverbank settles due to liquefaction, as shown in the figure,

the ground under the riverbank can't support the weight of the riverbank

and is flattened and deformed, causing the ground to extend transversely.

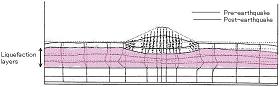

The surest way to prevent liquefaction-caused riverbank settlement is to

prevent the ground liquefaction under the riverbank. However, it is difficult

to improve the ground immediately under riverbanks that have already been

built. As such, we tend to take measures around the bottom of the slope

and reduce the riverbank settlement by preventing the liquefaction layers

under the riverbank from extending transversely. There are various methods

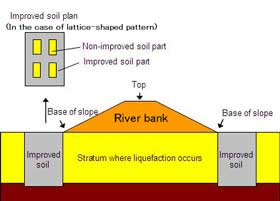

to prevent riverbank settlement; one typical technique is to create improved

soil by mixing cement in the ground (solidification method). To reduce

the cost of engineering work, the ground is often improved in the shape

of a lattice pattern. We have assumed a medium-sized earthquake in the

seismic design standard to decide on the dimension and strength of the

improved soil. However, we have not figured out how safe the improved soil

is, nor how it fractures when a large-scale earthquake occurs such as the

Hyogo-Ken Nanbu Earthquake in 1995 or the Mid-Niigata Prefecture Earthquake

in 2004. We conducted a model experiment to determine stability and fracture

pattern of lattice-shaped improved soil when an earthquake occurs.

In the experiment, we installed a lattice-shaped improved soil designed

in accordance with conventional standards based on a medium-sized earthquake

around the bottom of the slope, and added a shock similar to that of a

large-scale earthquake such as the Hyogo-Ken Nanbu Earthquake in 1995.

The result was as follows:

(1) Against a large-scale earthquake, the riverbank settlement volume in the case without a lattice-shaped improved soil was twice as large as that of the lattice-shaped improved soil. We confirmed that the lattice-shaped improved soil is effective in reducing riverbank settlement.

(2) For large-scale earthquakes, we did not confirm any damage to the lattice- shaped improved soil. Even for a conventional seismic design based on a medium-sized earthquake, we confirmed that a certain level of safety is ensured.

(3) When simulating a larger earthquake, the lattice-shaped improved soil

was fractured, but the riverbank settlement volume did not increase after

the fracture.

We will accumulate experimental data and propose a rational seismic design method to improve soil for a large-scale earthquake.

(Contact : Soil Mechanics and Dynamics Research Team)

Clinical studies using removed bridges built in the past

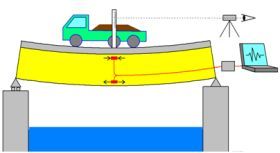

(Photo-1) Dump truck loading test |

(Photo-2) Shaking test using human power |

(Photo-3) Image of strain measurement |

(Photo-4) Damage to floor slab |

PWRI established the Center for Advanced Engineering Structural Assessment

and Research (CAESAR) in April. The CAESAR started clinical studies such

as behavior measurement, non-destructive investigation of deterioration

progress, and loading test of removed members using bridges built in the

past to be removed as a part of studies to solve problems from actual bridge

deterioration and damage cases.

In Japan, many bridges were built in the era of rapid economic growth of the 1960s and 1970s. Now they are aged and need appropriate maintenance. We will focus on these old bridges.

After the establishment of the CAESAR, we conducted an investigation test using the Route No.452 Asahi Bridge located in Ashibetsu City, Hokkaido in late October.The outline of the bridge is as follows:

Bridge name: Route No.452 Asahi Bridge (Ashibetsu City, Hokkaido)

Opening date: 1953

Structure type: Continuous steel I beam bridge with 3 spans (Reinforced concrete floor slab)

In the investigation test, we installed strain gauges on the bridge and

conducted a loading test using a heavy dump truck (Photo-1) and a shaking

test by having people repeatedly jumping together on the bridge (Photo-2).

We measured the stress and vibration of the bridge.

We will continuously implement such investigations, such as behavior measurement of an entire bridge using actual bridges and member strength test of removed bridges, and collect study results to establish investigative and diagnostic methods for deteriorated and damaged bridges.

(Contact : CAESAR)

Test of garbage biogas adaptability to road patrol cars:

Approach to reduction of CO2 emissions

Regional refuse disposal facilities (Recyclean) |

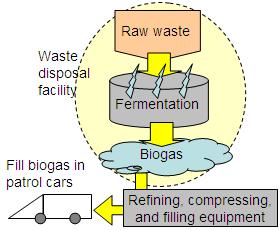

Biogas refinement flow |

Fueling gas in CNG road patrol cars (Tank capacity: 27m3) |

The Machinery Technology Research Team studies patrol cars running on biogas

generated from refuse disposal facilities and works on CO2 reduction.

This study investigates the adaptability of unused energies in cold regions with low temperature and snowfall when effectively using unused energies and substantially reducing CO2. We will introduce the status of this study.

The regional refuse disposal facility (Recyclean) managed and administrated

by the Association for Nakasorachi Sanitation Facilities (Hokkaido: Takikawa

City, Ashibetsu City, Akabira City, Shintotsukawa Township, and Uryu Township)

treats garbage through a methane fermentation process each day and uses

the garbage biogas generated as fuel for generators and boilers in the

facilities. However, extra gas of 10,000m3 or more per month are generated and burned. We are now conducting an experiment

to use the extra gas as fuel for CNG (compressed natural gas) cars using

refining, compressing, and filling equipment owned by the Hokkaido Regional

Development Bureau of Ministry of Land, Infrastructure, Transport, and

Tourism. Cars are used for everyday road patrol services of the Hokkaido

Regional Development Bureau.

The biogas is made by organic materials such as garbage. If the food chain

is taken into consideration, this matter originates in plants, which carry

out photosynthesis, so even if CO2 is emitted from gases burned eventually, it is carbon-neutral. The Cold-Region Machinery Technology Research Team analyzed the emission gas to figure out the actual amount of CO2 emissions. As a result, we compared the biogas usage and the gasoline usage in terms of emission gas component, and the amount of CO2 emissions for biogas was about 30% lower than that of gasoline. Travel

distance from the biogas is approximately 6,300km from late June to the

end of November, the equivalent of saving about 980 liters of gasoline.

We will obtain collect travel distance and fuel consumption data by actually using biogas to road patrol cars for one year. The team will extract unique problems in cold regions, such as snow and ice, car start-up performance, and power performance, and consider measures to handle these issues. We hope to contribute to the achievement of the CO2 reduction goal through these activities, and propose a model that can be rolled out not only in cold and snowy regions but also throughout Japan.

(Contact : Machinery Technology Research Team, CERI)